Interested in Pumps?

Get Pumps articles, news and videos right in your inbox! Sign up now.

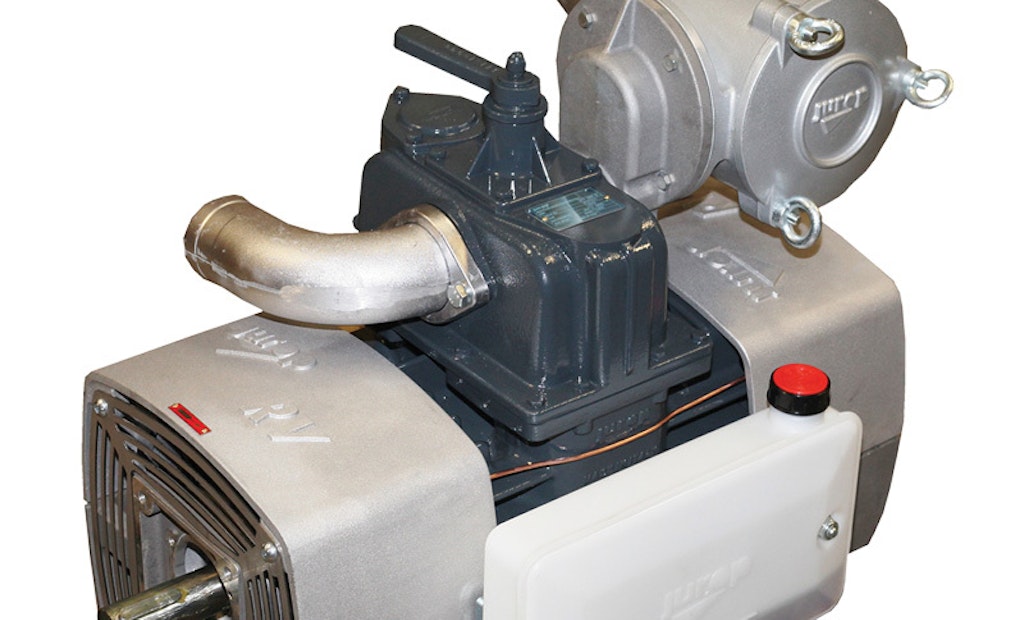

Pumps + Get AlertsThe new Jurop RV Series rotary vane vacuum pumps offer contractors better sustained performance through more efficient, dual-fan cooling technology, along with quieter operation.

The RV360 requires an input of 1,100 to 1,300 rpm and creates output of 360 cfm of free air (332 cfm at 18 inches Hg), and produces a maximum pressure of 30 psi. The RV 520 requires an input of 1,100 to 1,300 rpm and moves 520 cfm of free air (466 cfm at 18 inches Hg), and produces maximum pressure of 30 psi.

Both units operate at or near 76 decibels, says Todd Devecsery, director of sales for CEI Chandler Equipment Inc., a Jurop business partner and distributor.

Available in multiple drive configurations (gearbox, hydraulic or belt-drive), both pumps feature counter-opposing cooling fans that dissipate heat from the housing more efficiently. That, in turn, allows the pumps to operate at a higher rate of vacuum and pressure for longer periods of time, Devecsery says.

“The RV models feature two fans that face each other, one at each end of the pump,” he explains. “That pretty much doubles the fresh air blowing across the housing.”

Other features include automatic lubrication; independent, side-mounted, one-gallon oil tanks; and an integrated, four-way valve manifold. The RV360 requires 16 hp to produce vacuum and the RV520 requires 32 hp. The RV360 weighs 430 pounds; the RV520 weighs 540 pounds.

Generally speaking, both models can replace almost any existing pump, as long as the cfm range and drive configuration are similar and the hose is the same diameter. “In most cases, you could install it yourself,” Devecsery says. “Most pumps that are similar in terms of cfm are similar in size and weight and should be interchangeable.”

To make replacements easier, the pumps also come in packages that could include a muffler, a secondary shutoff, a drive component, a stand and the pump in one ready-to-bolt-on unit.

“Our packages are for pumpers who are looking for bolt-on applications,” Devecsery says. “They allow the end user to upgrade their trucks with very little labor … with a package of components that have been proven and tested and are engineered to be used together.”

The pumps’ quieter operation helps improve employee safety and, in some cases, enables contractors to get work they otherwise might not obtain within industrial facilities or in heavily populated areas with low-decibel work requirements.

800/342-0887; www.chandlerequipment.com.