Interested in Onsite Systems?

Get Onsite Systems articles, news and videos right in your inbox! Sign up now.

Onsite Systems + Get AlertsAdvanced Treatment Units

Anua PuraACE

The PuraACE from Anua is a drop-in-tank reactor pod for treating high-strength waste from restaurants, convenience stores or other facilities. The pods can be added to existing residential or commercial treatment systems that are overloaded. Treatment occurs by a submerged aerated filter process to reduce BOD, COD and ammonia. It includes passive alkalinity control that regulates pH without chemical addition. The pod housing isolates aeration to keep heavy solids from mixing. The open-channel media prevents clogging, while the airlift recirculation enhances retention time. Multiple reactor pods can be utilized for larger flows and loads. 336-547-9338; www.anuainternational.com.

NextGen Septic technology

Treated water exiting NextGen Septic technology meets higher water-quality standards than treated water leaving a typical centralized wastewater treatment plant. The system is suitable for sites traditionally requiring costly drainfield construction due to size restrictions and/or hilly, rocky, clay or sandy soil conditions. It is approved for surface discharge in Kentucky, and it uses a combination of anoxic treatment of the raw wastewater followed by aerobic degradation of the contaminants. An ultra-filtration membrane further treats the water before being disinfected using ozone. Treated water has less than 15 mg/L of BOD5, less than 2 mg/L ammonia, less than 1 mg/L phosphorus and no TSS. Ozone decomposes to oxygen, which increases the dissolved oxygen level in the discharged water. This treated water can be used for irrigation or to resurrect a clogged leachfield. 513-673-3583; www.nextgenseptic.com.

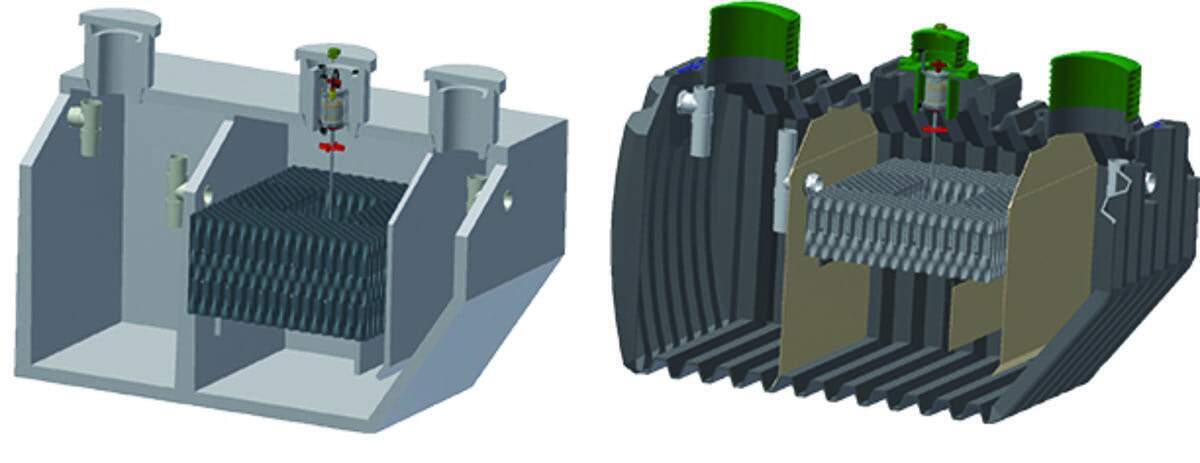

SeptiTech STAAR filter systems

SeptiTech STAAR (Smart Trickling Anaerobic/Aerobic Recirculating) filter systems are designed for residential and commercial properties with minimal operator oversight, while delivering consistent treatment during peak, low or intermittent flows. Using an unsaturated, engineered textile media to treat wastewater that meets strict permit limits, the commercial filter system provides a simple, automatic equalization and clarification process for 500- to more than 150,000-gpd flows. The biological trickling filter technology also maintains low levels of Nitrate-N, with all below-grade components that fit in watertight concrete, plastic or fiberglass tanks. Smart technology allows the system to go into a sleep mode to achieve lower operating costs and power requirements. Systems are ETV-EPA verified and NSF/ANSI Standard 40/245 certified. 800-753-3278; www.septitech.com.

Commercial Onsite Treatment System

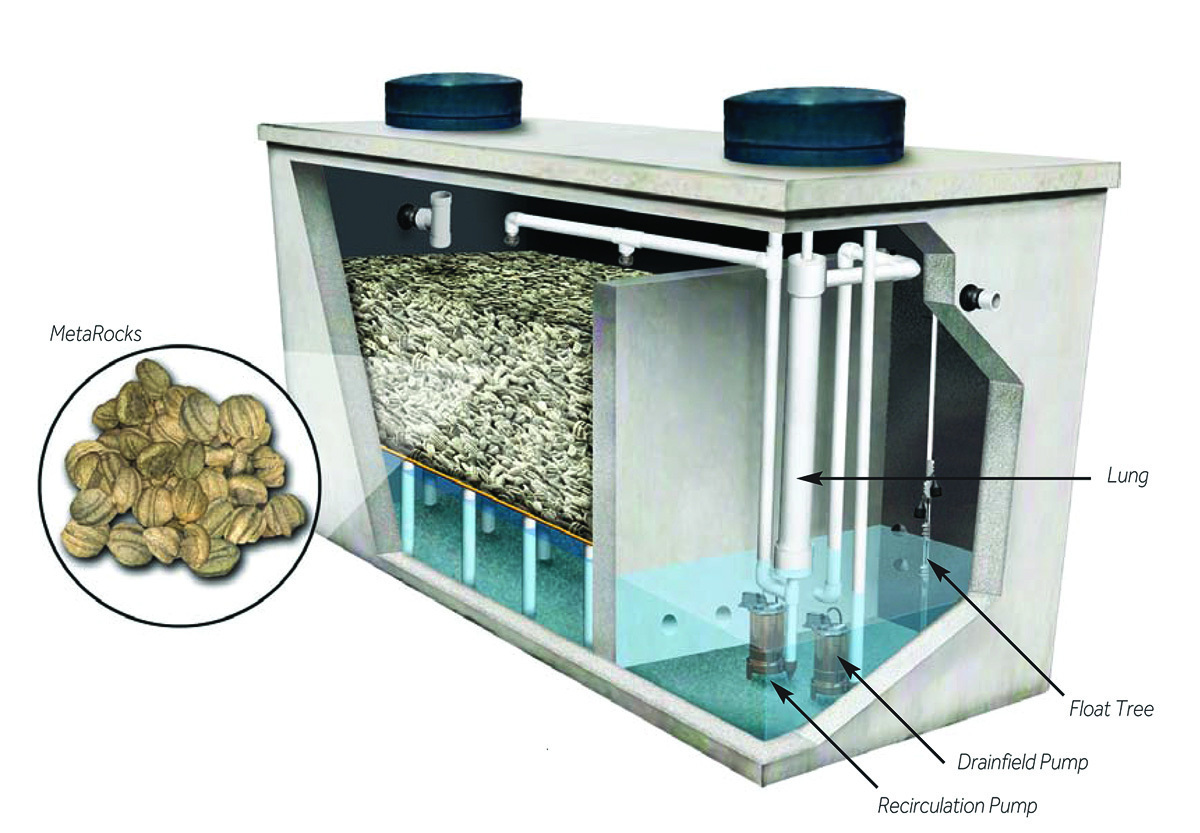

Eliminite Commercial C-Series

The Commercial C-Series system from Eliminite is designed to provide reliable treatment with emphasis on total nitrogen reduction for high-strength waste applications such as worker camps, RV parks, restaurants, ski and golf resorts, breweries, mines and agricultural operations. It is designed to work with locally sourced tanks and components when possible. MetaRocks treatment media is designed to withstand a variety of high-strength waste-loading scenarios, particularly where clogging and odor control are major considerations. The system is scalable and may be adapted to suit specific phasing requirements, site constraints and unique demands. 888-406-2289; www.eliminite.com.

Nitrogen Reduction Systems

Jet Inc. J-1500CF Series

The J-1500CF Series nutrient-reducing BAT media plant from Jet Inc. offers variable capacity in an NSF-245-tested treatment system. It provides complete effluent treatment from 500 to 1,500 gpd. The 500- and 800-gpd PLT Series tanks are the lightweight, rotational molded alternative to the concrete J-1500CF Series. The seamless polyethylene tanks are easy to transport and install in difficult site conditions. The system uses a 700++ aerator, effluent filter and the Jet 197 control panel, which cycles the aerator to reduce nitrogen by over 60%. 800-321-6960; www.jetincorp.com.

Norweco Singulair Green

The Singulair Green advanced treatment unit from Norweco offers a solution to difficult tank delivery concerns such as limited site access and steep grades. The system treats up to 600 gpd. Treatment occurs in the pretreatment, aeration and final clarification chambers. Activated sludge recirculates to the aeration chamber via a biostatic sludge return mounted in the aeration/clarification wall. Effluent in the clarification chamber enters the biokinetic filter and is equalized and filtered. Model TNT, or total nitrogen treatment, reduces total nitrogen by more than 68%. Designed for easy installation, operation and maintenance, the TNT system minimizes effluent nitrogen concentrations reliably and economically. 800-667-9326; www.norweco.com.

Orenco Systems AdvanTex AX20-RTUV

The AdvanTex AX20-RTUV treatment system from Orenco Systems is a self-contained module designed to treat typical septic tank effluent to better than secondary standards, with nitrogen reduction and UV disinfection. It is designed for homes with up to four bedrooms and suited for small sites with poor soils or sites requiring shallow burial. It helps protect surface waters and aquifers and can be an effective solution for areas that have strict discharge limits, according to the maker. It is installed following a septic tank equipped with Biotube effluent filters. The unit eliminates the need for separate recirculation, treatment, discharge and disinfection tanks and basins; and it reduces the number of risers and lids needed in the treatment train. 800-348-9843; www.orenco.com.

UV Disinfection Equipment

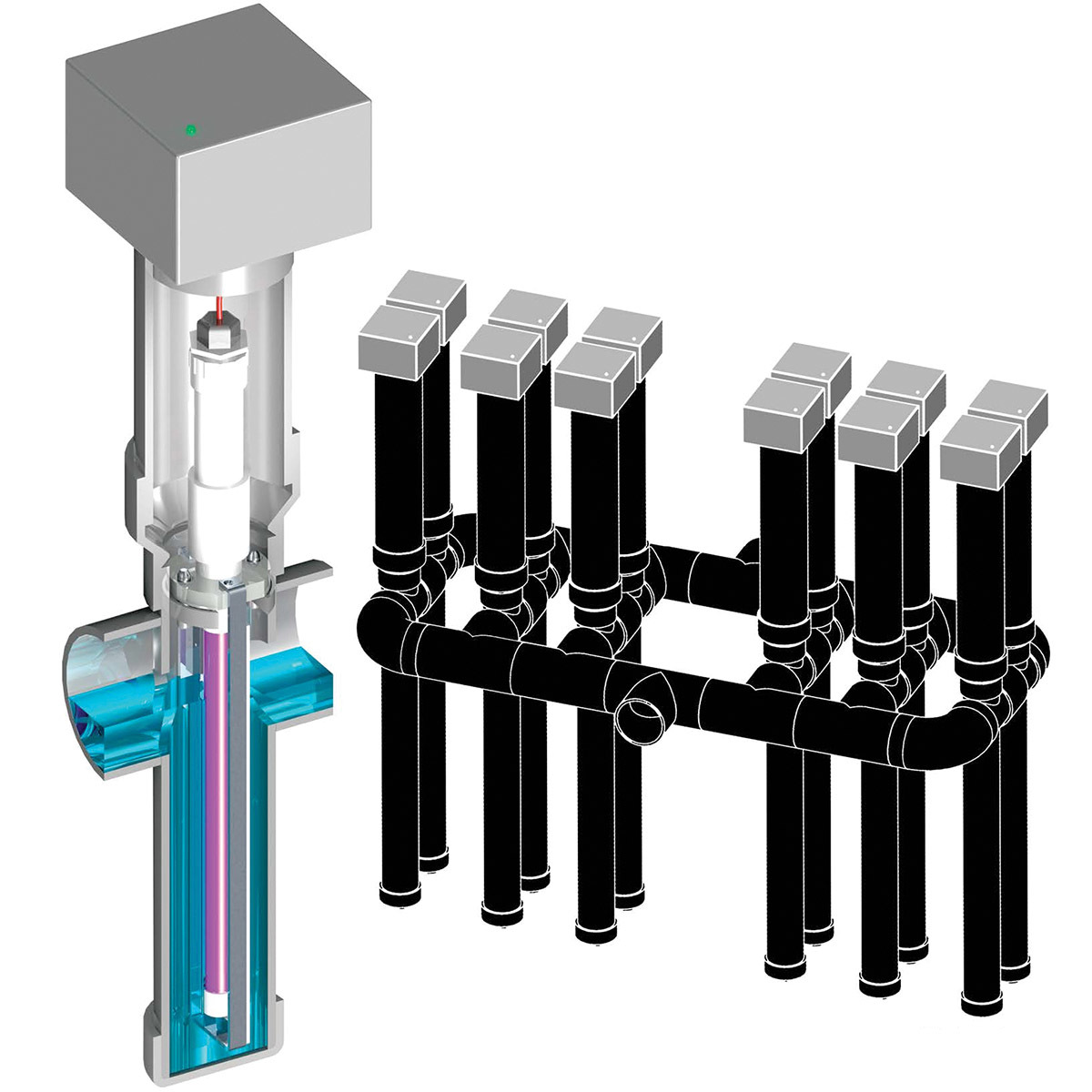

SALCOR 3G UV Wastewater Disinfection Unit

The 3G UV Wastewater Disinfection Unit from SALCOR is used for residential, commercial and municipal applications, and it is UL-certified NEMA 6P floodproof and NSF/Washington State Protocol six-month tested (with 21 upstream treatment systems). It inactivates bacteria/virus pathogens, including superbugs. Rated at 9,000-gpd gravity flow, it is meant as a reliable building block for large-water recovery/reuse systems. When installed in 12-unit parallel/series arrays with ABS pipe fittings, systems can disinfect more than 100,000 gpd. Gravity flow equalizes without distribution boxes. Each unit has a foul-resistant Teflon lamp covering, two-year long-life lamp with efficient installation, minimal annual maintenance and energy use of less than 40 watts. 760-731-0745; www.salcor.world.