Interested in Onsite Systems?

Get Onsite Systems articles, news and videos right in your inbox! Sign up now.

Onsite Systems + Get AlertsAerobic Treatment

Knight Treatment Systems White Knight Microbial Inoculator Generator

The White Knight Microbial Inoculator Generator from Knight Treatment Systems offers an enhanced form of aerobic treatment that introduces, cultivates and releases selected microorganisms. It is designed to be simple to install in most septic tanks. It can be used to retrofit outdated aerobic treatment units and package treatment plants and enhance the performance of community and high-strength wastewater treatment systems and septage processing facilities. 800-560-2454; www.knighttreatment.com.

SeptiTech STAAR

SeptiTech STAAR (Smart Trickling Anaerobic/Aerobic Recirculation) filter systems are designed for multifamily domestic and high-strength commercial wastewater systems with flows of 100 to more than 150,000 gpd. The systems use partially submerged media to treat high organic loads. The simple, automatic and reliable equalization and clarification process treats high-organic loads that integrate with other technologies and accessories, according to the maker. The biological trickling filter technology also maintains low levels of Nitrate-N with all below-grade components that fit in readily available concrete, plastic or fiberglass tanks. Smart technology allows the system to go into a sleep mode that will dial down activity and eventually shut power off until normal flow conditions are detected. This reduces operating costs and power requirements. 207-333-6940; www.septitech.com.

Aeration Pumps/Systems

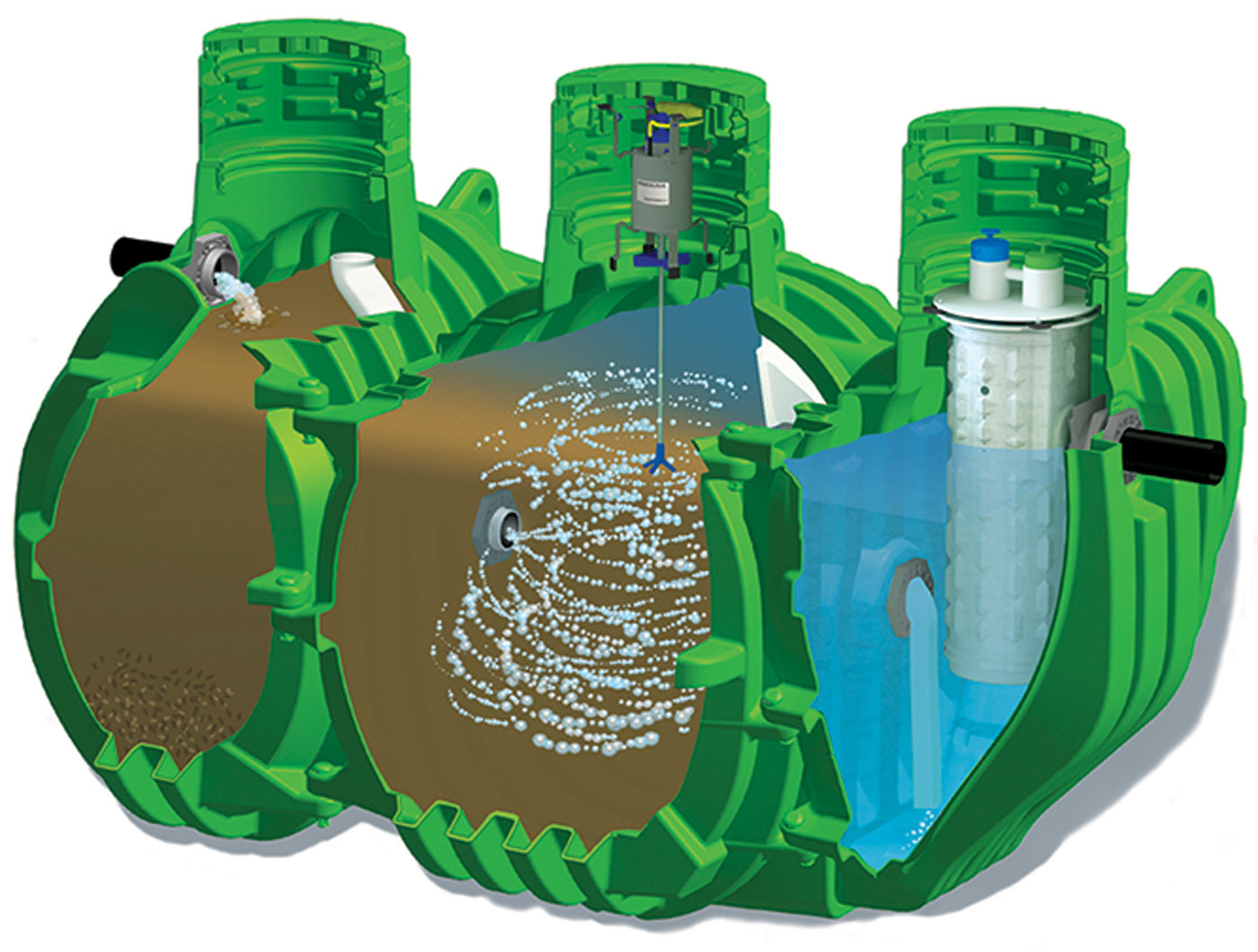

BioMicrobics MicroFAST

Available from 500- to more than 9,000-gpd applications, MicroFAST wastewater treatment systems or MicroFITT-ee (energy-efficient version) from BioMicrobics are advanced, integrated wastewater treatment systems with aeration and submerged fixed-film, suitable for residential and commercial applications. With the SFR feature of the FAST technology, alternate modes of operation include intermittent operation to reduce electricity usage up to 45% and extra denitrification from the already approximately 70% nitrogen reduction (NSF 245). Its biosolids treatment and sludge digestion enable cost-effective treatment with less maintenance. The effluent meets secondary quality requirements and can be distributed to a soil treatment system or water reuse applications. 913-422-0707; www.biomicrobics.com.

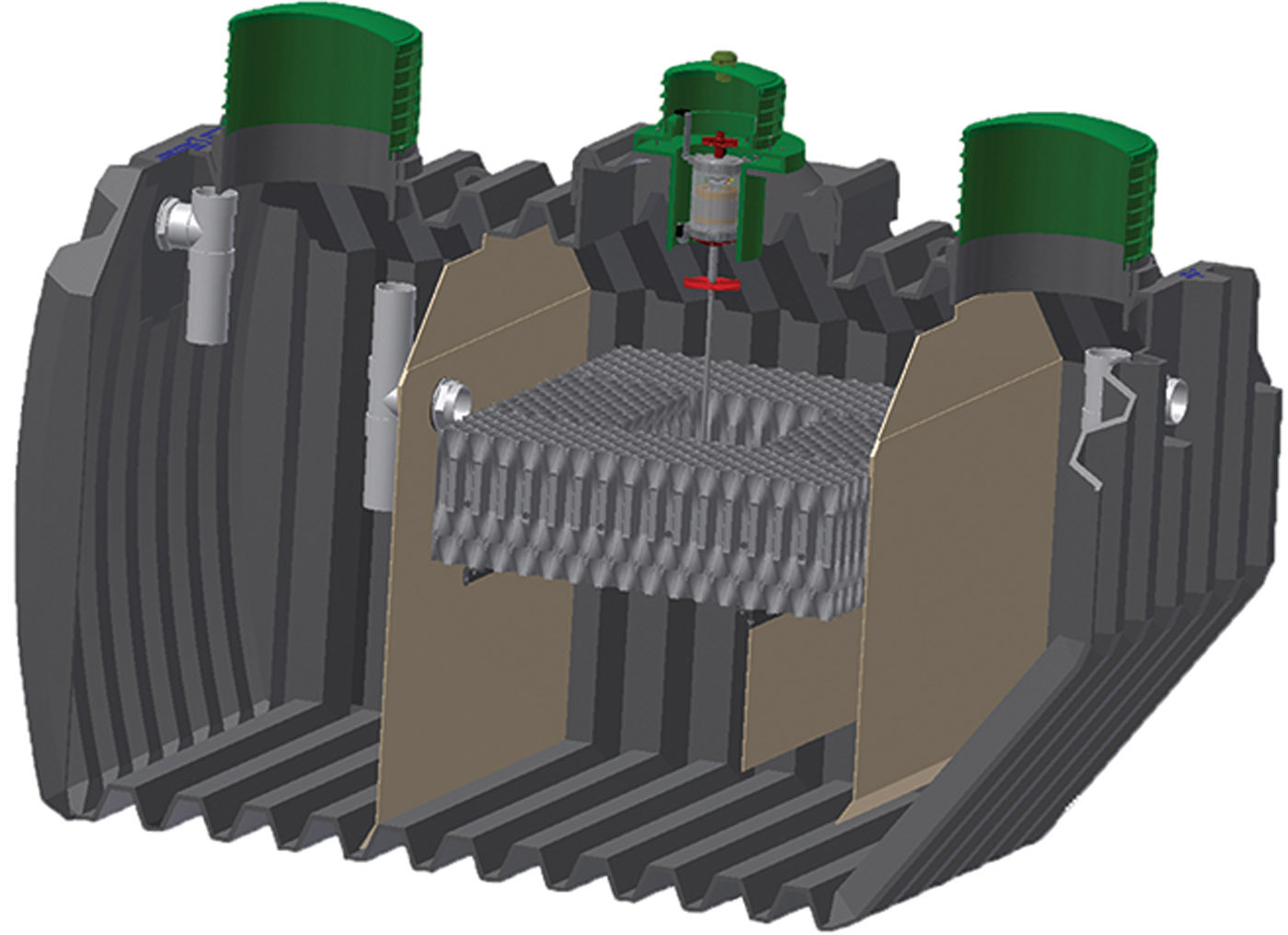

Clarus Environmental Fusion

Clarus Environmental’s Fusion systems are drop-in wastewater treatment units designed for decentralized applications where effluent quality must meet or exceed secondary treatment standards. They are designed for residential, commercial and small community applications and are available in 450- to 4,000-gpd treatment capacities. All models up to 800 gpd are NSF/ANSI Standard 40 certified to produce effluent quality of 9 mg/L CBOD5 and 9 mg/L TSS. The design enables installation without a pretreatment tank, making it suitable for sites with limited space. Effluent disposal options include conventional trenches, dosed systems, drip irrigation or disinfection with direct discharge. 800-928-7867; www.clarusenvironmental.com.

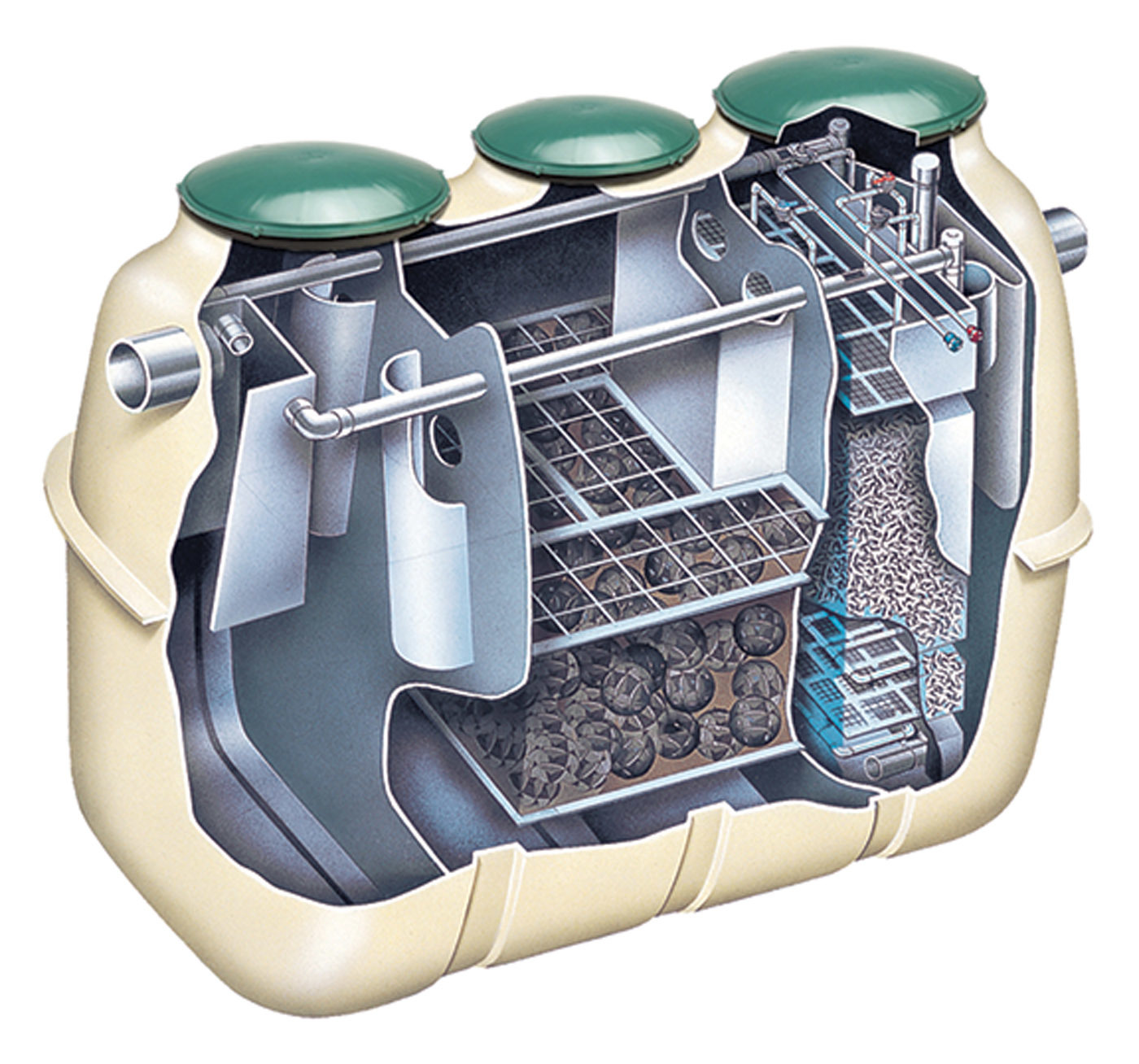

Jet Inc. BAT Media Plants

Jet Inc. BAT Media Plants offer variable capacity in an NSF 40- and 245-listed treatment system. The precast concrete J-1500 Series provides complete effluent treatment from 500 to 1,500 gpd with the convenient option of a fully integrated pump tank. The 500- and 800-gpd PLT series tanks are the lightweight, rotational molded alternative to the concrete J-1500 Series. The seamless polyethylene tanks are easy to transport and install in the most difficult site conditions. 800-321-6960; www.jetincorp.com.

NextGen Septic GenX Retrofit

GenX Retrofit septic technology from NextGen Septic can be installed in any approved septic tank and is designed to repair a clogged soil drainfield. It includes a compact, stand-alone, automated, two-stage treatment system for domestic sewage that produces a clean-water output. The sewage is collected in a tank, where solids break down under anoxic conditions, while the wastewater is aerated with biomedia and low-noise submersible pumps in the secondary compartment. The second stage occurs in a separate treatment unit, treating nitrogen and phosphorus through a no-maintenance membrane and ozone disinfection system. The process lets water and salt pass through, while rejecting the solids and dissolved organic contaminants to create an output suitable for surface discharge. According to the maker, the clogged field begins to percolate water in as little as eight to 12 weeks when the biomat is thin enough to allow water to get through at a reasonable rate. 513-673-3583; www.nextgenseptic.com.

Aeration Systems

Geomatrix Systems SoilAir

SoilAir from Geomatrix Systems intermittently aerates the drain/leachfield and surrounding soils rather than constantly aerating wastewater in a tank. This process allows rapid rejuvenation of failed septic systems, extends the life span of new leachfields and enhances treatment, according to the maker. Systems can serve single and multifamily homes, as well as challenging and high-strength waste streams, such as restaurants, hotels, marinas, laundromats, health care facilities, grocery stores, food processing facilities and convenience stores. 888-764-5247; www.soilair.com.

Commercial Onsite Treatment Systems

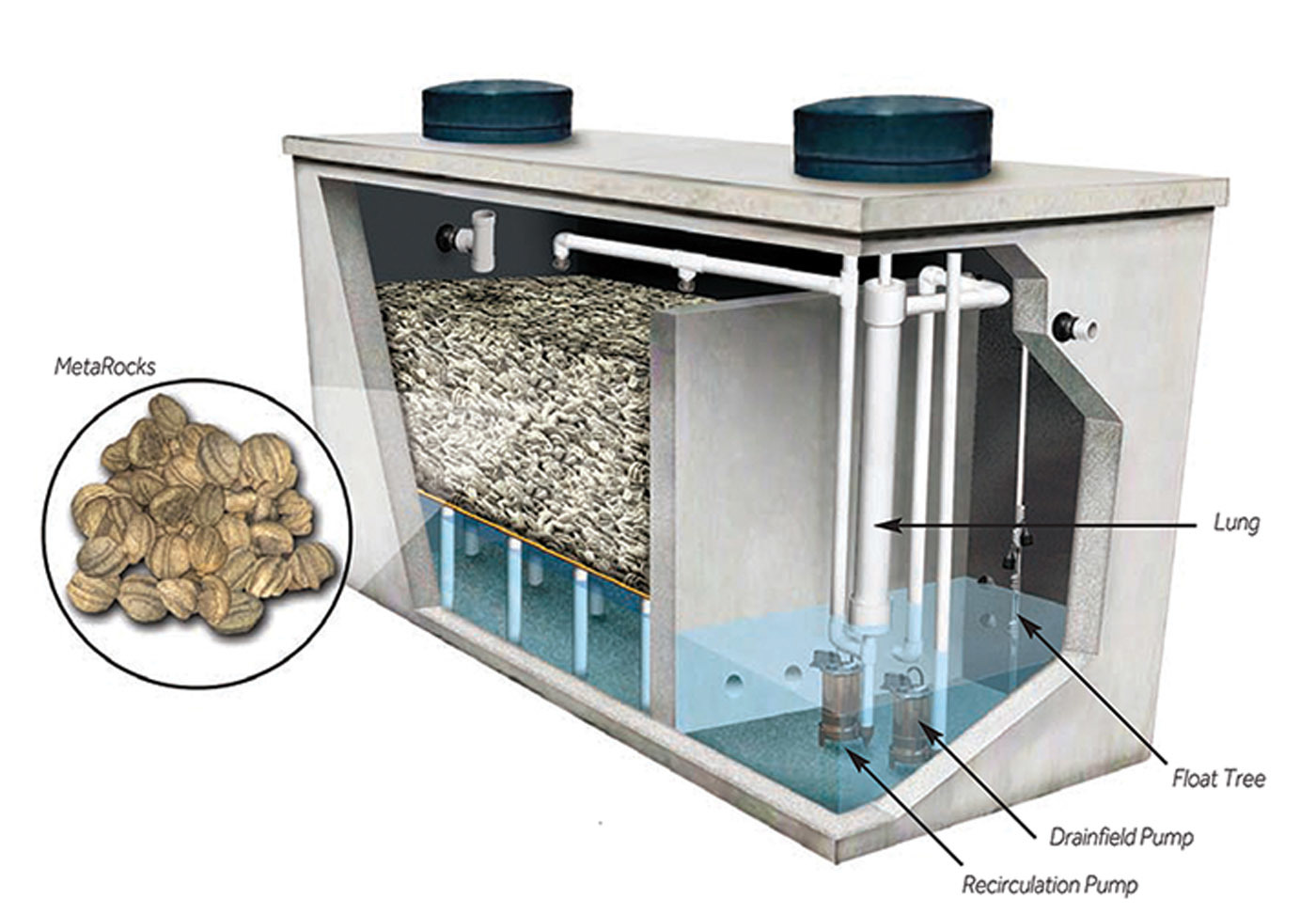

Eliminite Commercial C-Series

The Commercial C-Series system from Eliminite is designed to provide reliable treatment with emphasis on total nitrogen reduction for high-strength waste applications such as work camps, RV parks, restaurants, ski and golf resorts, breweries, mines and agricultural operations. It is designed to work with locally sourced tanks and components when possible. MetaRocks treatment media is designed to withstand a variety of high-strength waste-loading scenarios, particularly where clogging and odor control are major considerations. The system is scalable and may be adapted to suit specific phasing requirements, site constraints and unique demands. 888-406-2289; www.eliminite.com.

Nitrogen Reduction Systems

Anua Puraflo Dn

The Puraflo Dn peat fiber biofilter system from Anua provides enhanced denitrification below 20 mg/L through recirculating 50% of the treated effluent back to the front end of the septic tank, according to the maker. Flow proportioning is accomplished through simple adaptations to external plumbing, allowing for a single-pump system with no aerators. In recirculation mode, each module is rated for domestic strength at 240-gpd total hydraulic loading equivalent and 120-gpd forward flow. It can be designed and installed as a combined treatment and effluent dispersal system. Treated effluent exits the modules via weep holes around the perimeter at the module base and flows into the dispersal system situated directly beneath the modules. Available dispersal system options are in-ground pad or mounded pad. 336-547-9338; www.anuainternational.com.

Norweco Singulair TNT

The Singulair TNT (Total Nitrogen Treatment) system from Norweco is an advanced wastewater treatment system designed to reduce total nitrogen by more than 68%. Certified performance data from NSF Standard 245 verifies that average effluent contains 7 mg/L nitrate, 12 mg/L total nitrogen, 4 mg/L CBOD5 and 9 mg/L TSS. The system offers flow equalization, effluent filtration and low electrical usage. It is designed for easy installation, operation and maintenance to minimize effluent nitrogen concentrations, according to the maker. Nitrogen reduction is achieved without requiring effluent recirculation or the addition of chemicals. All treatment is accomplished within the tank. 800-667-9326; www.norweco.com.

Scienco/FAST - a division of BioMicrobics BioBarrier MarineMBR

The BioBarrier MarineMBR from Scienco/FAST - a division of BioMicrobics uses the same design as the land-based BioBarrier membrane bioreactor and BioBarrier HSMBR (high-strength MBR) systems. The complete, optimized design of these MBRs simplifies the settling, screening, direct aeration and ultrafiltration of wastewater to remove 99.9% of contaminants, according to the maker. It is certified to NSF/ANSI 40 Class 1, NSF/ANSI 245 (nitrogen reduction), NSF/ANSI 350 (water reuse) and EN 12566-3 standards. The blackwater/graywater treatment system establishes the material, design, construction and performance requirements for onsite residential and commercial applications. Installed in watertight tanks, the systems also meet water-quality requirements for the reduction of chemical and microbiological contaminants for nonpotable water reuse. 913-422-0707; www.sciencofast.com.

Recirculating Filters

Delta Treatment Systems ECOPOD-N

The ECOPOD-N fixed-film bioreactor (FFBR) system from Delta Treatment Systems is a self-contained device that houses engineered PVC media designed to treat domestic wastewater. Five models accommodate daily flows of 500 to 1,500 gpd, with customizable options for commercial applications up to 100,000 gpd. It is suitable for individual residential installations, cluster designs and commercial wastewater treatment applications. It is certified to ANSI/NSF International Standards 40 and 245 and is Federal Housing Administration and Veterans Affairs acceptable. It can be inserted into a standard-size septic tank or vault to provide quiet, odorless operation, and it is suitable for intermittent usage with an average nitrogen reduction greater than 50%. It also minimizes sludge production, reducing pumpout frequency, according to the maker. 800-219-9183; www.deltatreatment.com.

Ecoflo Biofilter

The Ecoflo Biofilter is an energy-free treatment that uses a renewable, compostable coconut husk filter, giving it a low carbon footprint. Most models come preassembled and ready to use. 800-632-6356; www.ecoflobiofilter.com.

UV Disinfection Equipment

SALCOR 3G UV Wastewater Disinfection Unit

The 3G UV Wastewater Disinfection Unit from SALCOR is used for residential, commercial and municipal applications, and it is UL-certified NEMA 6P flood-proof and NSF/Washington State Protocol six-month tested (with 21 upstream treatment systems). It inactivates bacteria/virus pathogens, including superbugs, according to the maker. Rated at 9,000-gpd gravity flow, it is meant as a reliable building block for large water recovery/reuse systems. When installed in 12-unit parallel/series arrays with ABS pipe fittings, systems can disinfect more than 100,000 gpd. Gravity flow equalizes without distribution boxes. Each unit has a foul-resistant Teflon lamp covering, two-year long-life lamp with efficient installation, minimal annual maintenance and energy use of less than 40 watts. 760-731-0745; www.salcor.world.