Interested in Industrial?

Get Industrial articles, news and videos right in your inbox! Sign up now.

Industrial + Get AlertsYou’ve gone through the extensive process to ensure you’ve selected the right power take-off for your work truck. It matches up with the truck’s transmission and all the other considerations have been made, such as the mounting location, the rotation of the driven equipment, and what kind of torque and horsepower need to be delivered to that equipment to get the job done. But that’s just the first step. Now you have to make sure that PTO is not going to break down on you prematurely.

It starts with proper installation.

“The leading cause of PTO failure is improper installation,” says Ben Gillum, product and applications specialist with Muncie Power Products. He’s part of a team that handles the most technical PTO troubleshooting inquiries from customers.

A key part of the installation is having the correct backlash setting between the transmission drive gear and the PTO input gear, says Gillum. A tight installation will cause excessive wear when the gears push together. On the other end of the spectrum, set the backlash too high and the gears will be loose, also potentially causing damage to the components.

“If the backlash is too low, it could literally break the teeth off the gears,” Gillum says. “If there’s too much, you may not be able to get the PTO flush. Maybe by torquing the bolts down you could pull it close, but you shouldn’t have to do that. If the backlash is right, you’re not pulling the transmission and PTO together. They ought to mesh comfortably.”

The ideal backlash setting is between 0.006 and 0.012 of an inch. That can be measured with a dial indicator, though Gillum says he knows of customers who can find that range simply by “feel.”

“They know by wiggling the gears back and forth between their fingers when it’s somewhere in that range, but we recommend using a dial indicator,” he says. “You usually know once you fire up the truck if there is a problem. If it’s quiet, you got the backlash right. If it’s rattling you need to tighten it more. If the gears are too tight, it will be whining.”

Another important part of installation is putting in a support bracket if necessary.

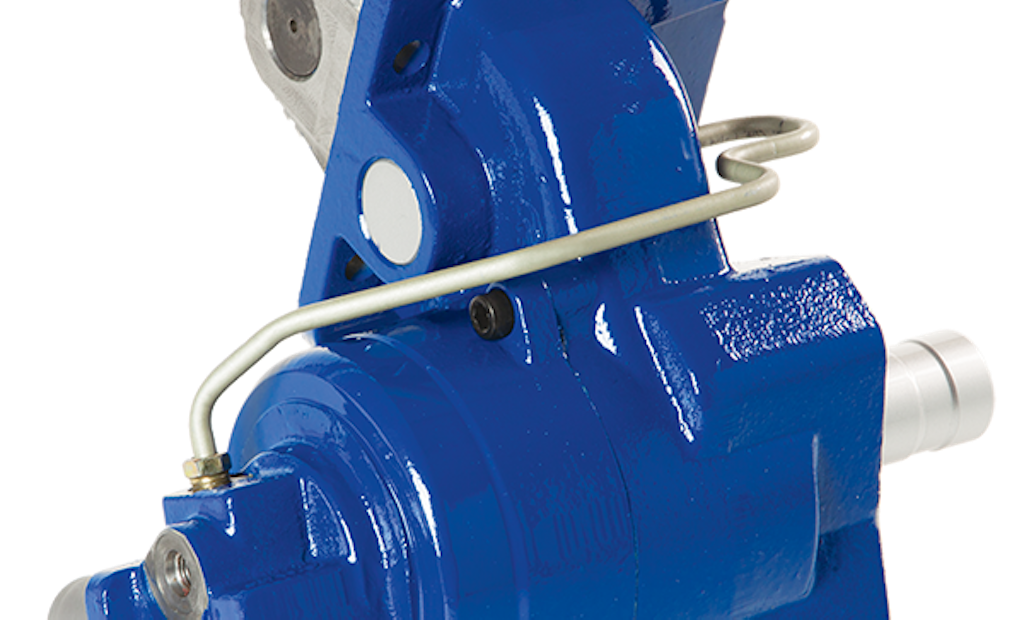

“Anytime you direct-mount a hydraulic pump to a PTO, if the weight of the pump, plus the hoses, plus the oil is over 40 pounds, or it’s more than 12 inches long, you must make a support bracket. We don’t supply one because it would be impossible to produce all the different combinations of brackets, so customers have to fabricate it themselves,” Gillum says. “They need to attach it to at least two bolts on the transmission and two bolts on the rear of the pump. That way the PTO is supported by the transmission, because they will be moving together and the PTO won’t be twisting and possibly breaking that way.”

After a successful installation, it’s time to practice good preventive maintenance as you put the truck to work. Gillum says all Muncie PTOs are shipped with an anti-seize compound already injected into the splines to protect against threading and corrosion.

“That helps right off the bat,” he says. “After that, there isn’t an exact maintenance schedule, but anytime there’s some sort of regular maintenance or lubrication on the truck, it’s a good idea to check the PTO shaft. It’s really simple to give a quick look at the splines and stick some grease in there if need be. You do that a couple times a year, and maybe a little more frequently if you’re in a heavy-use situation or a dirty environment.”

Gillum says every 100 hours is a good general grease schedule in high-use applications, but everyone should tailor it to their particular circumstances.

“You just have to get a good feel for your maintenance schedule,” he says. “It’s something that’s going to be individual to every application. Say you checked the PTO regularly and it took six months for it to get really dry the last time. The next time, don’t check it for another four or five months.”

Periodic inspection of the PTO is important because the signs of a dry shaft are not always obvious, says Gillum. You may not realize there’s spline threading or corrosion until it’s too late.

“You don’t really hear or see much,” he says. “It can just be some vibration once the shaft is dry and those teeth are together pretty tightly. And then if you’re in a humid environment or you’re doing off-road work and you get a splash under there, rust can start to form on the shaft. Anytime you have extra particles — rust or anything — in those splines, it eats away at them even faster. You don’t know anything is wrong until something like the pump can’t build as much pressure because the teeth aren’t engaged enough to be able to drive it.”

Good PTO maintenance also ties back into that very first step of selecting the right PTO. You may have a PTO that matches your transmission and is capable of powering your driven equipment, but is it truly the best choice?

“Part of it is how long do you want the PTO to last, period,” Gillum says. “If you don’t want to have to do things like replace gears a lot, I suggest going with a PTO that is more than capable of handling the horsepower and torque requirements you need to meet.”

Another aspect of the selection process is how you’re connecting the driven equipment to the PTO — remotely or directly. A direct connection means a hydraulic pump on the PTO that will begin the power transfer process for other equipment. A remote connection means a drive shaft extending from the PTO. Sometimes a hydraulic pump is the only option depending on the way the truck is set up. But even if using a drive shaft is possible, Gillum says a hydraulic pump application might work better from a maintenance perspective.

“With hydraulic fluid, you have metering capability and you get a lot more control,” he says. “You can start everything more slowly. When you engage the PTO, especially a clutch-shift PTO on an automatic transmission, if you’re putting a big load on it immediately, those clutches tend to slip in milliseconds and heat builds up extremely quickly in startup torque. You can fry a clutch pack really quickly. So applications that have a high startup torque, a hydraulic pump would be better even if they could use a drive shaft.”