Interested in Onsite Systems?

Get Onsite Systems articles, news and videos right in your inbox! Sign up now.

Onsite Systems + Get AlertsTake a look at this Diamond Environmental Services Septic Service company article featured 10 years ago in the April 2004 issue of Pumper magazine. We spotlight the company again in a follow-up story to see how the business has evolved over the last decade: “Pumper Rewind: Diamond Environmental Services Triples in Size.”

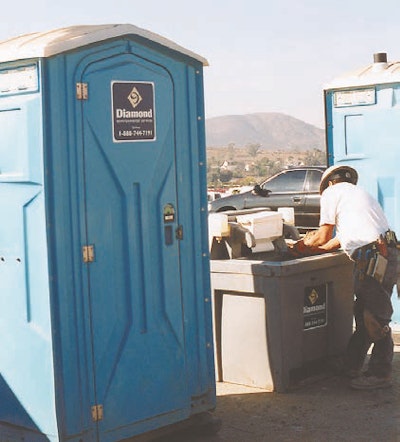

Eric de Jong started his portable restroom company, Diamond Environmental Services, in the fast-growing San Diego area.

But growth in the population is not the only reason for his quick success. Since he opened the doors in San Marcos, Calif., in 1998, he has built the business methodically, responding to customer needs, investing wisely in restrooms and service equipment, hiring with care, and training his team in clear, simple, consistent procedures.

Today, the business Eric started with 400 restrooms and 150 customers purchased from another company has 67 employees, roughly $5 million in annual revenue, and a diverse inventory of 5,500 toilets.

Starting off right

From the beginning, Eric knew the region needed a good restroom provider, and he knew the key to that was to have good employees. “Many of my key employees had worked with me in a solid waste company previously owned by my father, Arie de Jong,” says Eric. “Together we had the experience in sales and marketing, and we understood the importance of routing, maintenance, and dispatching. All of those essentials for the portable sanitation.”

At first, Eric and long-time friend Warren Van Dam (now operations manager) did everything. “Whatever had to be done, we did it,” Eric says. “Saturday, Sunday, we did it. Another key employee from the start was Kevin Conway (now sales manager), who came with impressive sales experience and important contacts.”

The timing was right for growth, as several smaller companies in the area were selling out. “We benefited greatly,” says Eric. “Things really took off. I attribute our success to basic marketing. We contacted all the companies we had served in the solid waste business. We mailed out brochures and flyers, explaining our services. We kept track of people pulling construction permits, and we contacted them.”

Diamond joined industry associations, including the Portable Sanitation Association International and the San Diego Sewer Haulers Association. Company personnel also attended the Pumper & Cleaner Environmental Expo International.

Eric later added septic pumping service and bought a local grease trap service company. But it was the toilet business that just kept growing. “It has never slowed down,” says Eric. “Eighty percent of our business is in portable sanitation. All this has happened because of a lot of hard work, and good people who had the vision.”

Fitting the image

Blue is the color of all Diamond toilets, and the company prefers Tuff-Way units by Satellite Industries Inc. “We have found these units hold up the best and need the least repairs,” says Eric. “We grew our inventory from the beginning by purchasing a load of toilets every three or four months, and by acquiring small companies.

The company’s 27 restroom service trucks are Fords and Internationals, all with tank and vacuum systems built by Southern California Tank in Chino, Calif. They are outfitted with 1,000-gallon waste and 400-gallon freshwater tanks and have Tuthill vacuum pumps. “We try to keep all our trucks below the 26,000 pounds gross vehicle weight,” says Eric. “That way the driver doesn’t need a special license.” Southern California Tank also outfitted the company’s two septic pumpers.

The Diamond image is important. The trucks are regularly washed, and the toilets are cleaned meticulously. “When a restroom comes back into the yard, we have a system where it gets inspected for any damage or major graffiti,” says Eric. “We bill the customer if that happens. Units are repaired if needed, and they all get pressure-washed before going back into the system.

“If the guys doing the washing find anything wrong, they kick the unit back for further repair. In the yard, there are four people at all times doing nothing but repairs and washing. We use 3,000 psi pressure washer with 190 degree water, made by Alkota Cleaning Systems Inc.”

Simplicity works

Right from the start, Eric’s philosophy was to keep things simple. “We realized that in order to be competitive we needed to have options for the customer,” he says. The company settled on three basic types of toilets – “a good, better, best” approach – and limited the number of restroom suppliers.

Diamond built its inventory in a disciplined way, adding units to fit customers’ needs. Customer demand led the company into luxury restroom trailer rental with units from Advanced Containment Systems Inc.

“We have 55 solar units made by NuConcepts, and they are important because of their special features, with the lighting, flushing and running water,” says Eric. “They are the next step beyond the standard portable. Mostly they are for special events. Sometimes they’ll be on a permanent location, such as a car lot or a large construction office. Other VIP units include a sink, paper towels and seat covers. We have a couple hundred of those, made by Satellite.”

The company also offers PolyJohn high-rise units, used in construction of multi-story buildings and parking structures. Holding tanks provide another line of business. Diamond has about one hundred 250-gallon tanks made by Kentucky Tank Inc. They’re deployed on large jobs for office set-ups that have no sewer connection. The inventory also includes 100 ADA restrooms, and 300 handwashing units.

Getting the word out

Diamond’s expansion has been driven by a progressive sales program. “We have territories given out for construction, temporary and permanent accounts, and also separate salespeople for special events – all of these throughout San Diego and South Riverside Counties,” says Eric. “We have a full-time sales manager, four people who work in construction, and two for special event sales.”

Employees perform best in an atmosphere of consistency. To that end, Diamond has uniformity in its procedures and its training. “We have one person who does nothing but train drivers,” says Eric. “He shows them the routes, how we clean, where and how we empty our trucks, how we maintain rapport with our customers, and how we handle paperwork and follow-up. It’s an important part of our business and a good reason we have had such success.”

Diamond takes the hiring process very seriously. “Actually that’s the scary part of the business, more than buying equipment and inventory,” Eric says. “You’re dealing with people and personalities and families. These are people with children, homes, and bills to pay. That’s why training is at the top of the list for us. We want these people to succeed. We want the company to grow and to sustain everyone.”

Eric hires bilingual people when possible, because Southern California’s population is about 30 percent Hispanic.

Customer care

Customers can be assured of personal attention at Diamond, starting with the first time they call. “I’m against voice mail,” says Eric. “We always have someone answering the telephone during the work week. On the weekends and in the evenings, it’s a voice recording where a message can be left. We respond promptly to all messages.”

As the company has grown, Eric has learned to delegate. The biggest challenge comes in the process of acquiring another company. That last happened in December 2003, and it meant integrating equipment and employees into the existing structure. There was extra work for the existing employees and special training to acquaint new workers with Diamond’s standards and procedures.

But even through times like those, sticking to the plan has ensured success for Diamond Environmental. It’s the training and the talent – and good timing certainly hasn’t hurt.

SIDEBAR: CYBER-ASSISTANCE

Eric de Jong started Diamond Environmental Services with modest expectations, but high hopes. Technology has helped the company to maintain quality service while growing rapidly.

Eric never considered using the old “map with pins” approach. “We took our knowledge and our system from the solid waste company our family owned and purchased the same business program, called WAM,” he says.

“This has the billing and routing and handles all the information for our customers. We generate a route on a daily basis for each driver. You need this kind of system in this market. If anyone loses a route sheet or it flies out the window, we can push a button and it’s there.”

In the future, Diamond will focus on the restroom business and keep on with its grease and septic pumping services. “We have not looked at branching into any other areas,” he says. “We want to focus on what we’ve got going. Why mess with success?”