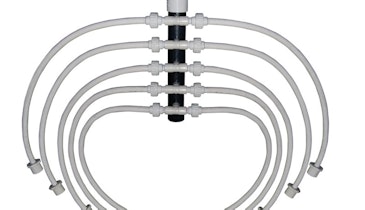

The smallest things can have a big impact when it comes to safely getting the job done right. That’s definitely the case with Water Cannon’s locking-collar quick-connect sockets, which were designed to offer pumpers added safety and versatility on hydroexcavation jobs.

Precision machined with male threads, the quick-connect sockets are made of hardened stainless steel to resist plug deformation when pressure spikes occur. The flow-through design provides an unrestricted bore with minimal pressure loss, giving operators smooth action and reliable service.

For extra safety, the brushed stainless steel sockets feature a push-and-snap locking collar with an alignment pin and easy-to-grip barreled ring for straightforward attachment. Replaceable O-rings ensure that users will have a watertight seal at all times, according to the manufacturer.

Water Cannon CEO Richard Kurtz says customers have responded favorably to the locking-collar safety mechanism, which prevents the high-pressure hose from detaching at the truck or at the trigger gun held by the operator.

“If a standard quick-connect is not snapped in place properly, it will fly apart,” he says. “Imagine the force of a standard self-serve car wash as 7,200 effective cleaning units (ECUs). And your average portable pressure washer has an ECU of 16,000. Now, imagine you’re the guy pulling the trigger on a hydroexcavation rig that delivers 20 gpm at 2,500 psi — or 50,000 ECU — and the quick-connect pulls apart, and the hose flies like a whip. Even worse, imagine if the hose flies off the trigger gun inches from the operator’s torso.

“Everyone appreciates the added safety, and we now have our products being used in a nuclear power plant,” says Kurtz. “I will take that as the ultimate compliment.”

The locking-collar quick-connect sockets are rated up to 210 degrees F and 6,300 psi for heavy-duty use. Water Cannon recommends coupling the sockets with stainless steel plugs that are interchangeable with most brands, and the company also suggests getting replacement O-rings to ensure the sockets continue to withstand hot water and aggressive chemicals.

The safety sockets come in various sizes and can even withstand pressure spikes from hydro-pulse jetter systems, according to Kurtz. 800/333-9274; www.watercannon.com.