Interested in Onsite Systems?

Get Onsite Systems articles, news and videos right in your inbox! Sign up now.

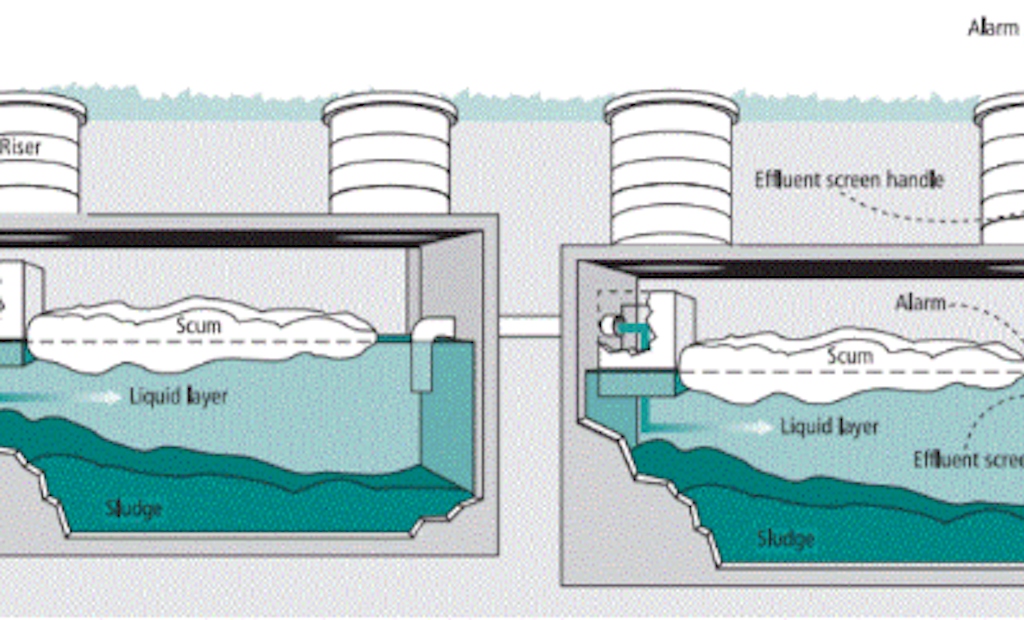

Onsite Systems + Get AlertsThe effluent that leaves the septic tank comes from the clear zone to minimize solids loading on the downstream components of the system. The baffle, tee or effluent screen at the outlet is designed to draw from the clear zone, retaining floatable or settleable solids in the tank.

The settling process requires time to occur, so the tank must be large enough to retain the wastewater in a turbulence-free environment for two to four days. Excessive flow and turbulence can disrupt the settling process as tank volume, size, shape and inlet baffle configuration are designed to minimize turbulence.

Effluent screens are designed to help keep solids in the tank. These devices trap suspended solids, reduce the total suspended solids concentration in septic tank effluent, and help protect the soil absorption field or other downstream treatment unit. They typically replace the outlet baffle in the final compartment of the tank. Septic tanks are designed to retain solids that accumulate over time. Some of these solids are byproducts of the waste treatment process, while others are materials that may not be capable of being processed, such as human hair. It is important that the solids are retained in the septic tank and not released to the drainfield. Excessive discharge of solids to the drainfield can cause it to plug and lose efficiency in treatment and dispersal of the normal liquid flow. If the problem persists, the drainfield may need to be replaced.

Independent research performed at Tennessee Technological University (Treanor, 1995) suggests that effluent screens do indeed reduce suspended solids as well as BOD in onsite systems. The study was performed as research for a master’s thesis, and was conducted at eight unrelated locations, under different loading rates and uses. Three different effluent screens were used. Statistical analysis showed that the screens significantly reduced the BOD and suspended solids in septic tank effluents.

Effluent screen design recommendations

1. For residential applications, place an effluent screen in at least a 1,500-gallon, two-compartment septic tank or use multiple tanks. Observations show that frequency of cleaning the screen is less when the screen is placed in the second compartment of a two-compartment tank than if placed in a single-compartment tank.

2. If sewage is pumped from a sewage ejector or grinder pump from a dwelling to a septic tank, the septic tank capacity should be increased 50 percent and should include either multiple compartments or multiple tanks. This is required because the discharge line cannot be restricted by a valve and because the pumping rate is so rapid, a great deal of agitation will take place in the first tank. The second compartment/tank is necessary for a quiet zone to exist for proper solids separation. The pump dose volume from the injector pump is recommended to be limited to less then 5 percent of the volume of the first tank or compartment.

3. If a garbage disposal is present or one may be added in the future, the septic tank capacity should be increased 50 percent and should include either multiple compartments or multiple tanks.

4. Be sure to select a screen for the hydraulic and organic loading rate anticipated from the facility. The smaller the screen, the quicker it will plug up and need to be cleaned.

About the author

Sara Heger, Ph.D., is an engineer, researcher and instructor in the Onsite Sewage Treatment Program in the Water Resources Center at the University of Minnesota. She presents at many local and national training events regarding the design, installation and management of septic systems and related research. Heger is education chair of the Minnesota Onsite Wastewater Association (MOWA) and the National Onsite Wastewater Recycling Association (NOWRA), and serves on the NSF International Committee on Wastewater Treatment Systems. Send her questions about septic system maintenance and operation by email to kim.peterson@colepublishing.com.