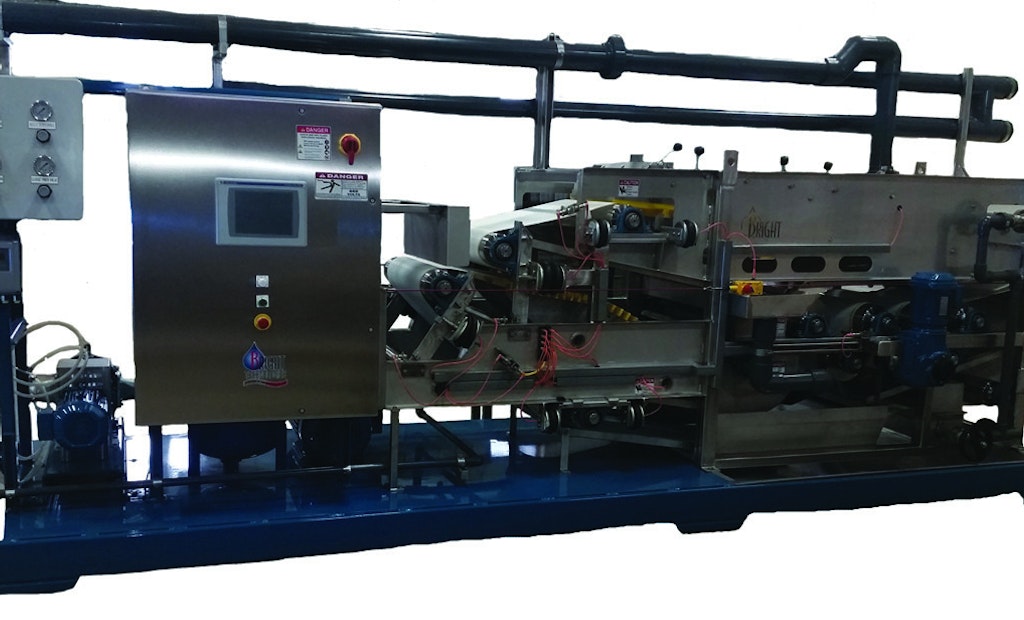

New and innovative grease handling equipment is designed to cater to a wide range of operational needs. Technologies like those below include compact belt filter presses with high-efficiency sludge dewatering capabilities, versatile grease units tailored for easy access and...

Elevate Your Septic Service Offerings With the Latest in Grease Handling Equipment

Popular Stories

Discussion

Comments on this site are submitted by users and are not endorsed by nor do they reflect the views or opinions of COLE Publishing, Inc. Comments are moderated before being posted.