As the need for efficient and eco-friendly dewatering solutions continues, the industry is meeting this challenge head-on with new robust and adaptable technologies. From skid-mounted belt presses with integrated components, compact belt filter presses featuring innovative design elements, to horizontally oriented dewatering drums equipped with self-cleaning features, these products embody the industry's focus on convenience, efficiency and optimized operation.

BDP Industries 3DP Belt Press

The skid-mounted 3DP Belt Press from BDP Industries is a turnkey dewatering solution with all components integrated on a hot dip galvanized skid for easy semi-permanent installation. This skid includes a booster pump, sludge pump, emulsion polymer system, hydraulic unit, controls and a 20-foot stainless steel screw conveyor. The press includes an independent gravity section, vertical pressure section and paddlewheel distributor. Features addressing odor control concerns include odor hoods, enclosed gravity sections, piped away filtrate and noise-reducing shower boxes. 518-695-6851; www.bdpindustries.com

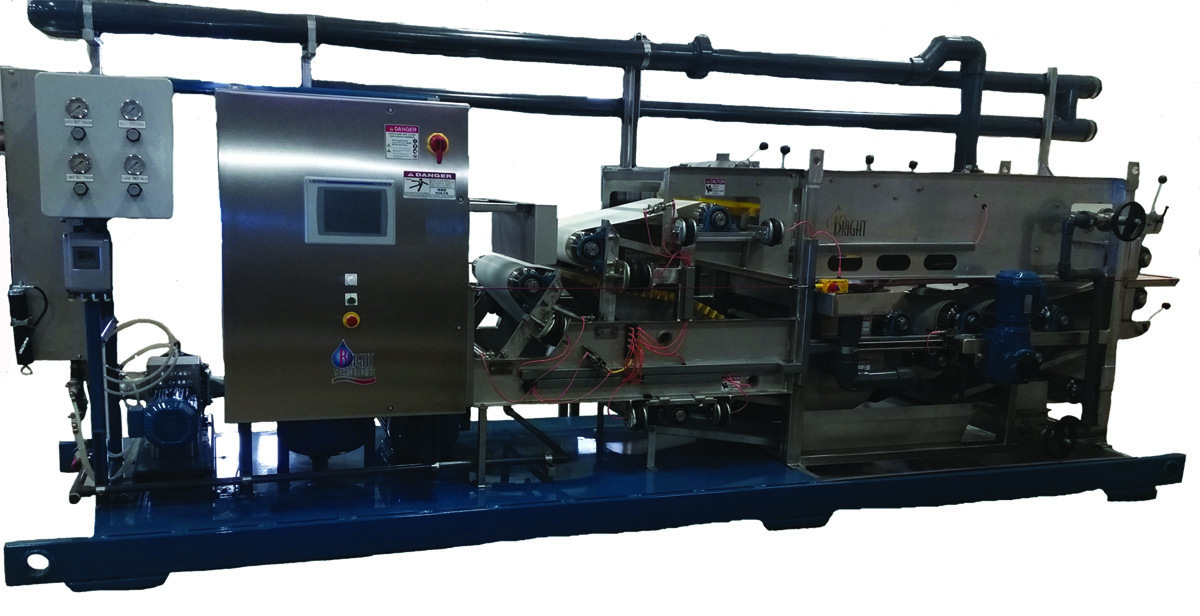

Bright Technologies, Division of Sebright Products, 0.6-meter skid-mounted belt filter press

The compact 0.6-meter skid-mounted belt filter press from Bright Technologies, Division of Sebright Products, has stainless steel frame and roller construction as well as radius wedge zone and wing roller for sludge dewatering. Components include a sludge pump, polymer system and wash-water booster pump. Options include a sludge flowmeter, air compressor and discharge conveyors. With a compact, walk-around skid design, it can be utilized in as little as a 10-by-20-foot floor area. The Boerger rotary lobe sludge pump has a maintain-in-place design offering ease of maintenance. Cake solids of up to 35% can be achieved. Rates of 25 to 50 gpm make it ideal for small applications or when a processor has outgrown dewatering containers. 800-253-0532; www.sebrightproducts.com

In the Round Dewatering horizontal drum

The horizontal biosolids dewatering system from In the Round Dewatering features a stainless steel drum with perforated plastic tile lining. The drum is mounted on a roll-off frame for easy transport and unloading. Trays contain discharge water. An 18,000- to 25,000-gallon batch is mixed with polymer before being filtered in the rotating drum, which is driven by a 1/2 hp variable-speed electric motor with a heavy-duty chain and sprocket. Turning eliminates crusting and wet pockets to produce uniform, consistent results. The dewatered material dumps easily, and the drum is self-cleaning. 317-563-2072; www.itrdewatering.com