Modern wastewater management relies heavily on advanced screening systems that effectively separate debris and inorganic solids from the water stream. These advanced systems significantly enhance the efficiency and cleanliness of wastewater management, leading to more streamlined operations. By implementing innovative technologies such as automated septage receiving stations and strainers, tools like the ones below not only provide faster unloading times but also bolster safety and control foul odors.

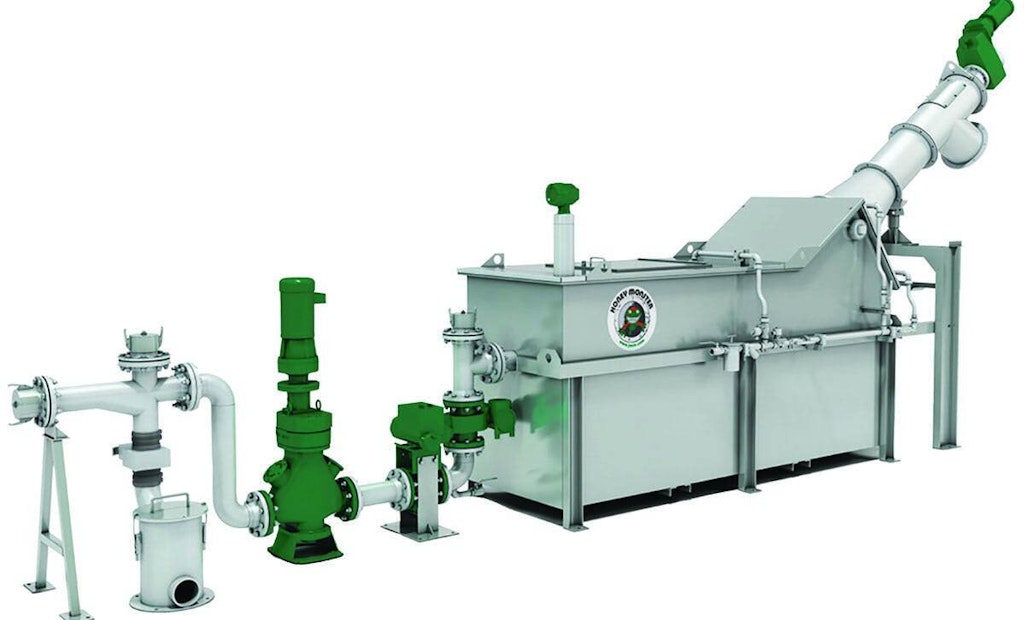

JWC Environmental Honey Monster

The Honey Monster septage receiving station and FOG receiving system from JWC Environmental is designed to ease the management of septage waste for the wastewater plant operator and the hauler. It quickly screens and processes septage, grease, FOG and sludge from vacuum trucks. The automated septage acceptance plant provides for cleaner handling of septage truck waste by reducing and separating unwanted solids such as rocks, rags, clothing, plastics and other trash, according to the maker. The combination of grinding, solids removal, washing and dewatering allows a typical septage truck to unload in 5 to 15 minutes. It is completely enclosed to ensure safety, vector control and containment of foul odors. The optional MonsterTrack metering and control system uses a flowmeter to track septage and provide accurate billing data for the facility and a receipt for the hauler. 800-331-2277; www.jwce.com

Lakeside Equipment Raptor Septage Acceptance Plant

The fully automated Raptor Septage Acceptance Plant from Lakeside Equipment is designed to remove debris and inorganic solids from septage tanks, grease traps, sludge, leachate and industrial waste. It includes the Raptor Fine Screen, which compacts and dewaters the captured screenings to a solids content of 40%. The screen’s rotating rake teeth penetrate the cylindrical screen bars, which prevents plugging and binding from grease and small debris. This allows for faster unloading times. The Raptor Acceptance Control System is a security access station that can be integrated to allow authorized haulers to unload their waste at the facility. Adding the data management and accounting system with the RACS station provides capabilities to track and invoice customers. 630-837-5640; www.lakeside-equipment.com

ScreencO Systems Trash Master 600 Auto Screen

The Trash Master 600 Auto Screen from ScreencO Systems uses gravity to separate the trash from the flow stream through a 6-inch inlet with dual fan spreaders. It is capable of power-offloading vacuum trucks with a single 6-inch offload or 2- to 4-inch offloads at the same time at a rate of up to 800 gpm. It comes with an aluminum hopper (stainless steel is optional), with an 8-inch outlet cam and 3/8-inch gapped 1/4-inch stainless steel bar screen. The stainless steel U-channel with ultra high molecular weight polyethylene plastic-lined titanium provides for years of wear, with a high strength alloy steel 11 1/2-inch shaftless screw that moves trash to a waste container. The U-channel has slotted drain holes and a center channel bar screen for cleaner and dryer trash. A custom-built stainless steel bar rake and cleaning brush are included for easy maintenance. 208-790-8770; www.screencosystems.com