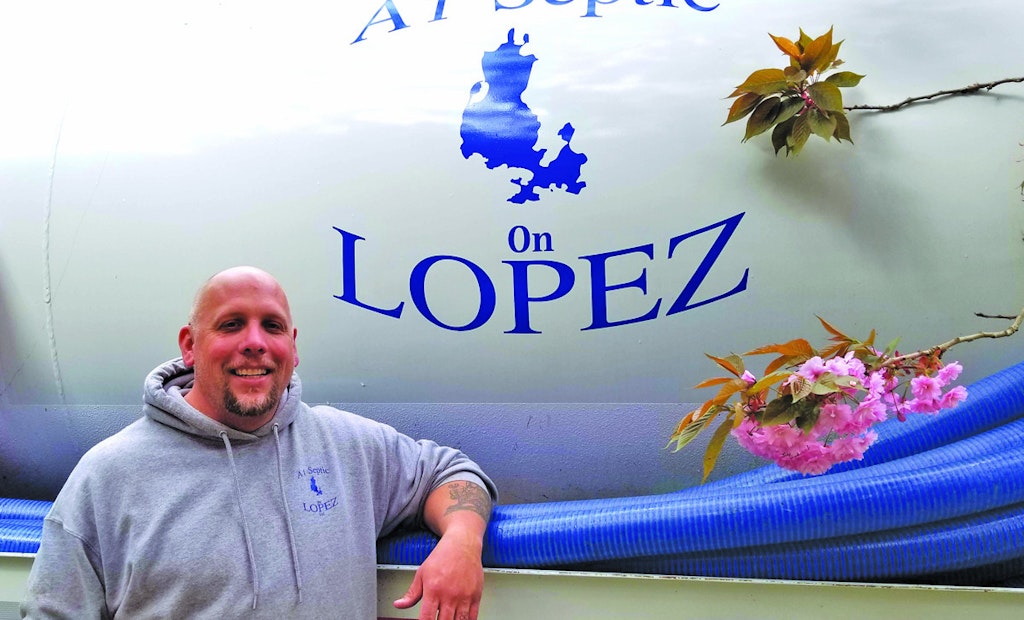

Jason Kramer with his 2001 International 9100 carrying a 3,600- gallon steel tank and National Vacuum Equipment Challenger pump.

Interested in Business?

Get Business articles, news and videos right in your inbox! Sign up now.

Business + Get AlertsName and title or job description: Jason Kramer, owner

Business name and location: A1 Septic on Lopez, Lopez Island, Washington, one of the San Juan Islands north of Seattle.

Services we offer: I started with pumping and then added inspections. That led to doing upgrades and repairs. I also do commercial pumping. And I’m working on my designer certification as my retirement plan.

Age: 49

Years in the industry: Eight years. I used to be a county road crew guy and I worked a couple of evenings a week for a company driving and emptying pumper trucks. We live on (Lopez Island) and have to take the trucks off-island for emptying. I worked there for a couple of years then decided to get into pumping. I found a truck in California which turned out to be great. You pay by the foot on the ferry, and this truck was as big as I could get and stay under 30 feet long, and I can still get down all the driveways with it. It’s a 2001 International 9100 with a 3,600-gallon steel tank and National Vacuum Equipment Challenger pump.

Association involvement: I’ve been in the Washington On-Site Sewage Association for six years.

Benefits of belonging to the association: Most of what I take advantage of is training and networking, getting to know the people in the industry. It really has been invaluable to me. And they do a lot of great stuff with legislation and trying to emphasize the importance of clean water and our role in it.

Biggest issue facing your association right now: Trying to recruit the next generation is challenging. There aren’t a lot of new people coming into it. But I think the classes WOSSA is bringing onboard are going to attract people because of the way they’re doing it. They’re keeping it interesting. If younger people can get introduced to the industry, I think WOSSA will be able to keep them interested. And they’re also doing a lot of scholarships, which is exposing the next generation to the industry.

Our crew includes: My old road crew boss, Tim Arnold, retired and now drives my tanker truck, a 1989 Freightliner customized by Erickson Tank & Pump with a 6,000-gallon stainless steel tank and Masport Cobra pump. We store septage in the tanker until it’s full, then Tim takes it off island for emptying a couple times a week.

Typical day on the job: My alarm goes off at 4 a.m. and I’m in my office by 5 to do paperwork. Then at 7:30 a.m. I work for the village sewer district, about 20 hours a week, which pays for my health benefits. It’s a sewer lagoon treatment plant with 200 houses on the system. I had never worked at a sewer district before, but they needed somebody and this district has septic tanks at all the houses so I was able to be a benefit to them. And the training I get there complements my business. By 11:30 a.m. I’m working my business and will typically work until dark, usually 60 to 100 hours a week. One of my favorite parts of the business is marketing so I take pictures and post those on Facebook.

The job I’ll never forget: When I pumped out my first RV, I bought an adapter to go under my truck and hook to the RV. It was a difficult connection because of the angle so it wasn’t sealed just right. I didn’t have anybody to teach me so I had to learn everything the hard way. I cracked the valve open a little bit on my vacuum hose, then opened up the RV black tank. It hammered and sprayed straight into my eyes. It was horrible. But I rinsed my eyes out and went back and figured it out.

My favorite piece of equipment: My service truck has all my tools and everything I could possibly need for any emergency. I also recently picked up a new 400-gallon aluminum tank. I had Erickson build it. It’s really nice because I can do RVs and portable restrooms, and on proprietary systems I can pump out the trash tank as part of the service, if it needs it, instead of going home to get the pumper truck. The truck is a 2005 Ram 3500. I bought it a couple of years ago and put a lot of new stuff on it, from steering linkage to cab lights, pipe rack, wheels, tires. I still need to figure out a freshwater system. It has a Masport pump. I’m bolting that to the truck because there’s a shelf at the front of the service bed because of pass-through storage, so I couldn’t have it bolted to the vacuum tank. The tank is removable with forks and I have cam locks on the hose to hook the tank to the power unit.

Most challenging site I’ve worked on: There was a job where I had to back down a narrow driveway and then the tank was 100 feet away and as steep as you could get without needing a rope to pull yourself up with. Between running the hoses down the hill, climbing back up, then pulling the hoses up, it took me about an hour and a half to pump that tank. I don’t think it had ever been pumped.

The craziest question I’ve been asked by a customer: “The drainfield is not draining, can’t you just dig it out and rebuild it?”

If I could change one industry regulation, it would be: As service providers we need to be able to work on electrical stuff — replace floats and pumps — instead of trying to find an electrician because it’s always an emergency when it happens. That’s been the most challenging thing for me. I’d like to be able to get a special electrical license so we could do the work. It’s not difficult work.

Best piece of small business advice I’ve heard: Never stop learning. I listen to podcasts and I’m always looking at WOSSA or NOWRA (National Onsite Wastewater Recycling Association) classes. One reason I like working at the sewer district is there is a lot of learning — and they’re paying for it.

If I wasn’t working in the wastewater industry, I would: Probably be working on a road crew, playing with those Tonka Trucks.

Crystal ball time – This is my outlook for the wastewater industry: I’m hoping we can get more people in the industry who care about what they’re doing. Some people are in it because it’s an easy way to make money, not because they care. I’d love to see that change. It seems that’s the way everything’s been going, especially since COVID. But that’s where marketing comes in. The more marketing there is for jobs and job fairs the better, especially if we get the bigger companies to be part of it, getting that knowledge out there.