Interested in Onsite Systems?

Get Onsite Systems articles, news and videos right in your inbox! Sign up now.

Onsite Systems + Get AlertsSome companies and jurisdictions have a maximum time period between septic tank pumping events, but we all know many variables impact the need for this septic service. How frequently a septic tank should be pumped depends upon the septic tank capacity, the number of people using the system and appliances that send waste to the tank, such as a garbage disposal.

Tank capacity and consequently detention time is reduced as solids build up. A tank detention time of less than 24 hours may result in some solids being discharged with the effluent and carried to the advanced pretreatment unit or the soil treatment area. To protect the downstream components, it’s necessary to periodically remove accumulated solids in the septic tank.

Proper septic system maintenance is on the rise in the U.S., and this generates more septage. If more than 60 million Americans are regularly pumping their septic tanks, that amounts to a lot of waste collected. While this is occurring, the price for hauling, disposal and treatment of septage is increasing due to growing environmental requirements, fuel and equipment costs, and labor.

PUMP AS NEEDED

According to the U.S. Environmental Protection Agency, factors that affect the physical characteristics of septage are climate, user habits, septic tank size, system design, pumping frequency, water supply characteristics, piping material, use of water-conservation fixtures, garbage disposals, household chemicals and water softeners. The two most common approaches to disposal of septage are taking it to a wastewater treatment plant for treatment or land applying it as a fertilizer and land conditioner.

Some treatment plants do not have the capacity to accept septage, and those that do have been increasing rates. Septage is typically more concentrated than municipal wastewater. The current challenge for many treatment facilities is to create enough septage disposal capacity to meet more stringent EPA regulations, while not overtaxing their treatment processes. Some plants charge a flat fee per load and a permit fee, while others charge based on actual volume received using flow metering to measure the gallons of each load. Some rates are determined not only by the flow but also the content or source of the septage.

Land application of septage is not allowed in some jurisdictions and is under increasing scrutiny. Application rates depend on the slope, soil type, depth of application, drainage class and hydraulic loading. As more land is developed across the U.S., land application sites are being taken out of production.

All these issues result in an increased cost to pump septic tanks. As an industry, we need to move away from a mandatory time period for septic tank pumping and only clean them as needed. In addition, we need to develop more options to deal with septage, such as regional septage processing facilities that could create compost.

THE 25% RULE

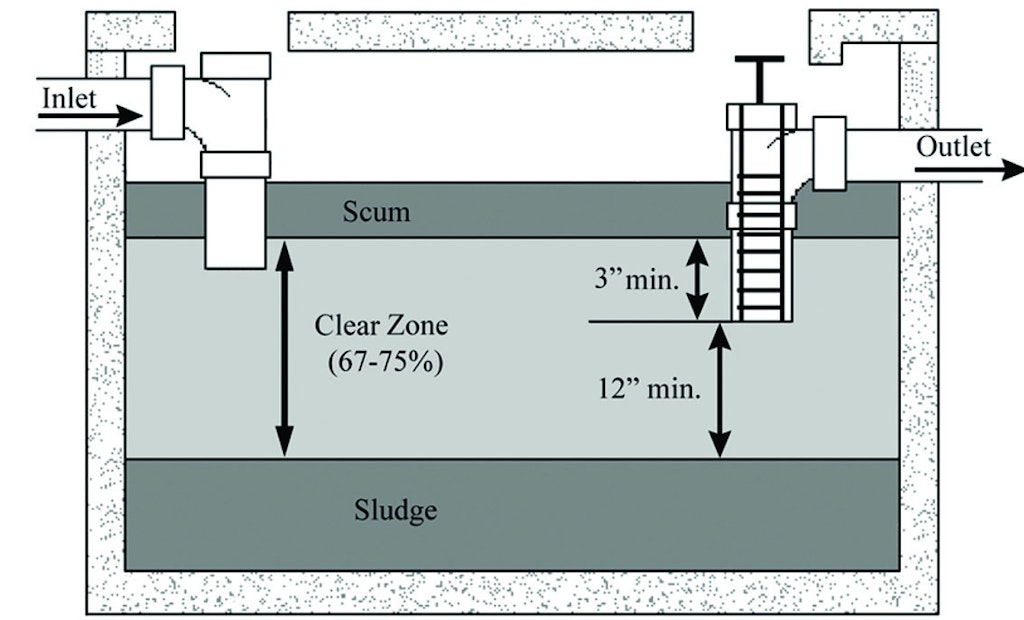

Although the specific requirements concerning septic pumping vary slightly based on the jurisdiction or system specifics, the general rule of thumb is that a tank should be cleaned if 25% of the initial liquid capacity is occupied by floating and settled solids (for example, 250 gallons in a 1,000-gallon tank). This can be seen in the accompanying diagram.

For example, if the sludge is 15 inches and the scum is 2 inches, we have a total of 17 inches and with a liquid depth of the tank of 60 inches we can calculate the percentage of sludge this way: (17 inches ÷ 60 inches) 100 = 28%. Septic tank needs to be pumped.

It is also true that we do not want sludge or scum accumulating too close to the outlet baffle/screen, so many regulations also state that the bottom of the scum layer should be several inches above the outlet and that the sludge be a foot or more below the outlet. If a pump tank is part of the system, we also want to check accumulations there. Sludge and scum being drawn into the pump can cause issues with the pump and overload downstream components.

This means scum and sludge accumulations should be periodically evaluated. For residential applications without advanced pretreatment, this should be done at a minimum of every two to three years. Even if the septic tank does not need to be pumped at the time of the visit, an overall evaluation of the tank can highlight other issues or repairs needed. These may include leaks at joints or connections, missing baffles or roots that — if left unchecked — could damage the system. Confirming manhole lid safety and integrity is also important.

For commercial systems, the frequency is a little harder to dictate as it will be based on the usage within the facility. However, it typically will range from quarterly to annual.

Pumping too frequently may prohibit development of a normal population of beneficial microbes. From the perspective of system longevity, it may be best to err on the side of pumping too often rather than not enough. However, excessive pumping increases the burden on septage disposal facilities and adds unnecessary cost for the owner. In addition, there is some evidence that when tanks are pumped every year or even more frequently, they sometimes do not develop normal scum and sludge layers.

The recommendation is to make pumping interval decisions based on actual tank conditions observed during your evaluation.