Interested in Disposal?

Get Disposal articles, news and videos right in your inbox! Sign up now.

Disposal + Get AlertsDewatering Equipment

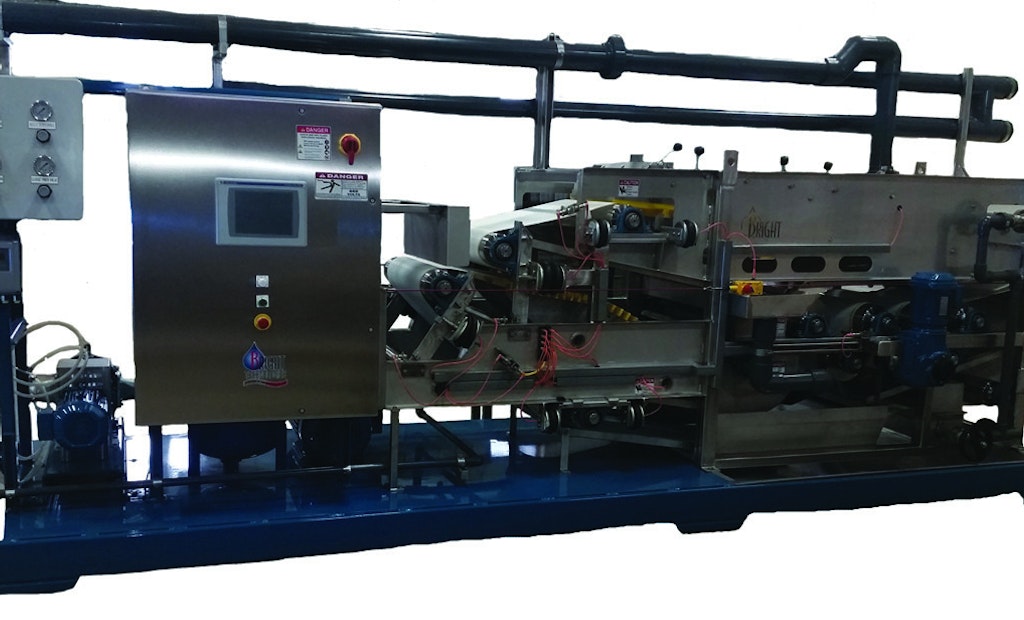

Bright Technologies, Division of Sebright Products, 0.6-meter skid-mounted belt filter press

The compact 0.6-meter skid-mounted belt filter press from Bright Technologies, Division of Sebright Products, has stainless steel frame and roller construction, as well as radius wedge zone and wing roller for sludge dewatering. Components include a sludge pump, polymer system and wash-water booster pump. Options include a sludge flowmeter, air compressor and discharge conveyors. The compact walk-around skid design can be utilized in as little as a 10-by-20-foot floor area. The Boerger rotary lobe sludge pump has a maintain-in-place design. Cake solids of up to 35% can be achieved. With rates of 25 to 50 gpm, it can be utilized for small applications or when a processor has outgrown dewatering containers. 800-253-0532; www.brightbeltpress.com.

In The Round Dewatering horizontal drum

The horizontal biosolids dewatering system from In The Round Dewatering has a stainless steel drum with perforated plastic tile lining. The drum is mounted on a roll-off frame for easy transport and unloading. Water trays allow containment of discharge water. An 18,000- to 25,000-gallon batch is mixed with polymer before being filtered in the rotating drum, which is driven by a 1/2 hp variable-speed electric motor with a heavy-duty chain and sprocket. The turning eliminates crusting and wet pockets to produce uniform, consistent results. The dewatered material dumps easily, and the drum is self-cleaning. 317-563-2072; www.itrdewatering.com.

Dewatering/Bypass Pumps

Boerger BLUEline

The BLUEline rotary lobe pump from Boerger is a self-priming, valveless, positive-displacement pump used to convey viscous and abrasive materials. There are 21 pump models in six series with pulsation-free operation, fully reversible rotation, dry-run capabilities and flow rates up to 7,500 gpm. The pumps are manufactured to be stable and wear resistant with a maintenance-in-place design that allows for all wetted parts to be easily replaced through the front cover without removing the pipe or drive systems. 612-435-7300; www.boerger.com.

Hydra-Tech Pumps S3T

The S3T 3-inch hydraulic-drive submersible trash pump from Hydra-Tech Pumps is designed for jobs such as construction sites and manhole pumping. It fits into 12-inch openings and is used where lightweight, high-volume trash pumps are needed. If being used for a job with limited solids, a small-hole water strainer is available. When combined with HT11 to HT15 power units, it is capable of flows up to 380 gpm. The safe and variable-speed hydraulic drive can be used where electric power is hazardous or impractical. 570-645-3779; www.hydra-tech.com.

Roll-Off Containers

AQUA-Zyme Disposal Systems ADS

The ADS 30-yard open-top roll-off dewatering unit from AQUA-Zyme Disposal Systems can be filled with 22,000 to 25,000 gallons of biosolids at 1% to 2% solids in about two hours. After draining for 24 hours, the unit can be picked up using a standard-capacity roll-off truck and transported for solids disposal. Sludge volume can be reduced by 80% with reductions to 98% in BOD, COD, FOG and TSS. Effluent is clear, the unit has few moving parts, and the size of filter media can be selected according to job requirements. Standard equipment includes a roll-over tarp system; side, floor and center screens; 1/4-inch floor plate; 7-gauge side plates; four door-binder ratchets; eight drain ports; two inlet ports; and a long-handle scraper. Units are also available in a 15-yard size. 979-245-5656; www.aqua-zyme.com.

Park Process Sludge King II

The Sludge King II roll-off dewatering container from Park Process uses filters that turn 90 degrees at the bottom of the container, leaving no standing water in the cake. This also increases the usable area of the filters by 33% over older containers with only one center filter wall. The increased filter surface area and the narrowed sludge compartments formed by the additional filter panel translate into drier cake formed in less time. 855-511-7275; www.parkprocess.com.

Pik Rite self-contained roll-off unit

Pik Rite self-contained roll-off units are fully operational at the pumping site without a chassis. The heavy-duty front platform holds the user’s choice of pump and a Kohler 25 hp electric-start engine. The tank is set up with a level indicator, rear sight eyes, 36-inch top manway, 20-inch rear manway, 3-inch intake with an internal 3-inch standpipe, and a 4-inch discharge. The low-profile, 12-inch primary shut-off is paired with a 10-gallon secondary shut-off. Spray-on liner under the hoses protects from scratches and promotes durability. Work lights and a safety beacon are mounted on the rear tank head, and a ladder is mounted on the side. Polished aluminum hose trays and custom paint finish are standard. Other customizable options are available. 800-326-9763; www.pikrite.com.

Pinnacle roll tarp sludge container

Roll tarp sludge containers from Pinnacle come standard in 20-, 25-, 30- and 40-cubic-yard capacities. The radius-bottom containers have 1/4-inch floors and 3/16-inch sidewalls. All containers are water-tested to the top of the container for 30 to 45 minutes and come standard with a side-roll tarp. Custom sizes, dewatering baskets and other modifications are available. All are blasted prior to painting, and the shell is powder coated. 256-840-8031; www.pinnaclemfg.net.

Screens/Strainers/Screening Systems

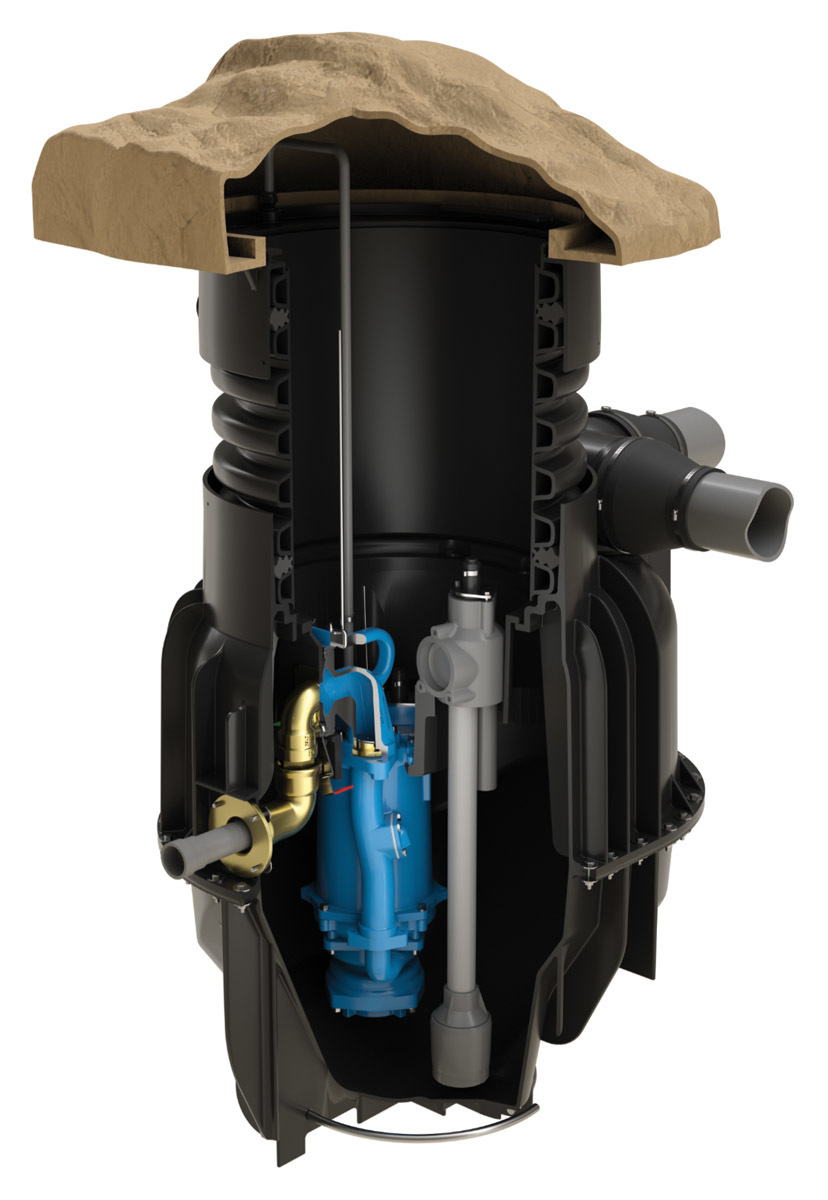

Crane Pumps & Systems Barnes Pressure Sewer EcoTRAN

The Barnes Pressure Sewer EcoTRAN from Crane Pumps & Systems is designed to provide a practical and environmentally safe alternative to traditional gravity sewers. Even in locations with difficult terrain, it reduces sewage infrastructure costs by allowing smaller diameter piping to be used in place of large complex septic sewage systems, making it a suitable sewer choice, according to the maker. It collects and grinds sewage in an underground basin, then transports it to a remote private or municipal wastewater treatment plant. 937-778-8947; www.cranepumps.com.

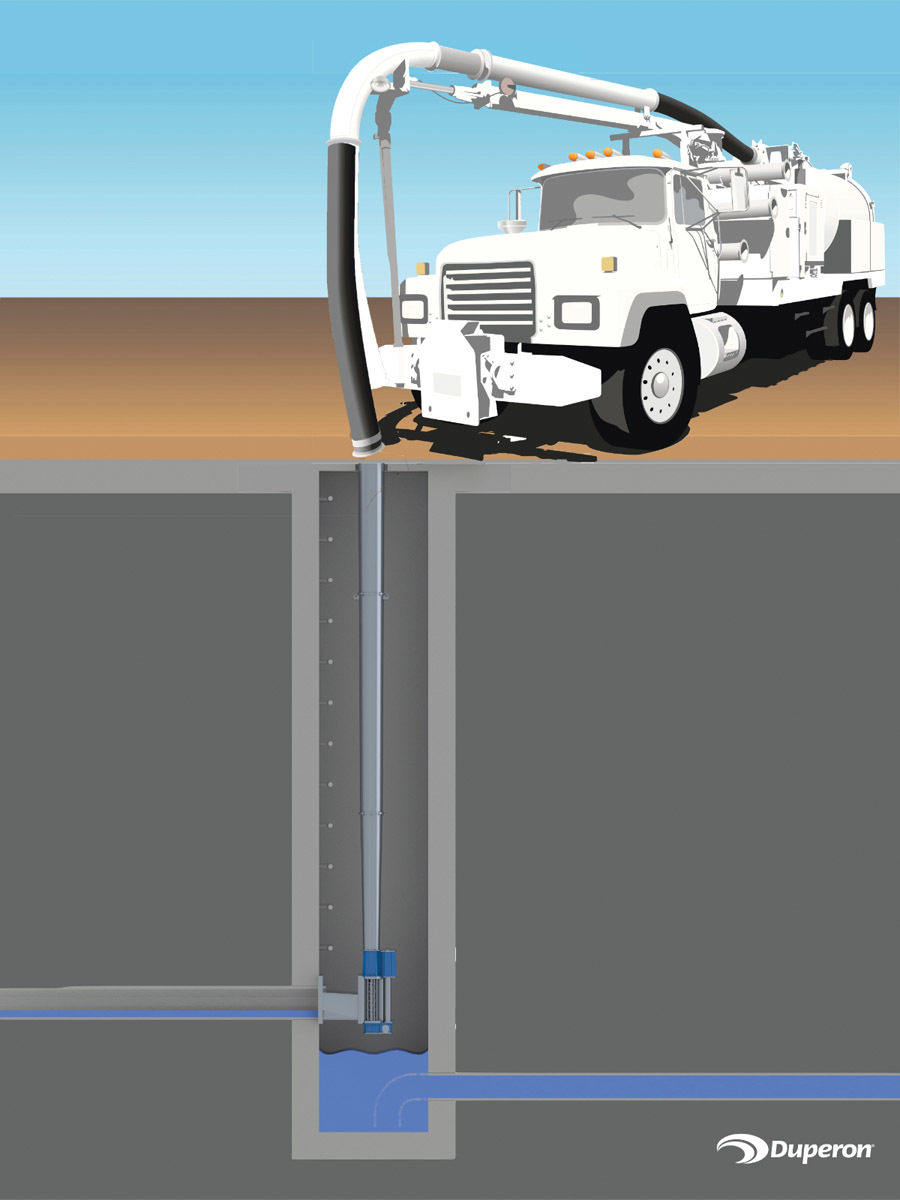

Duperon Dual Auger System

The Duperon Dual Auger System is deployed in targeted high-ragging manholes/wet wells to remove problematic debris and prevent chronic pipe and pump clogging. Removing wipes at (or near) the point they enter the sewer stops the problem where it starts without impacting downstream operations. The five-in-one system captures, dewaters, compacts, conveys and stores problematic debris in a below-grade discharge pipe where it can be emptied by vacuum trucks. This lets users transform emergency, dirty, unsafe and manual cleanouts into planned, safe and coordinated debris removal by vacuum truck operators. To use, uncover then insert suction tube into the discharge chute, remove debris and landfill. 800-383-8479; www.duperon.com.

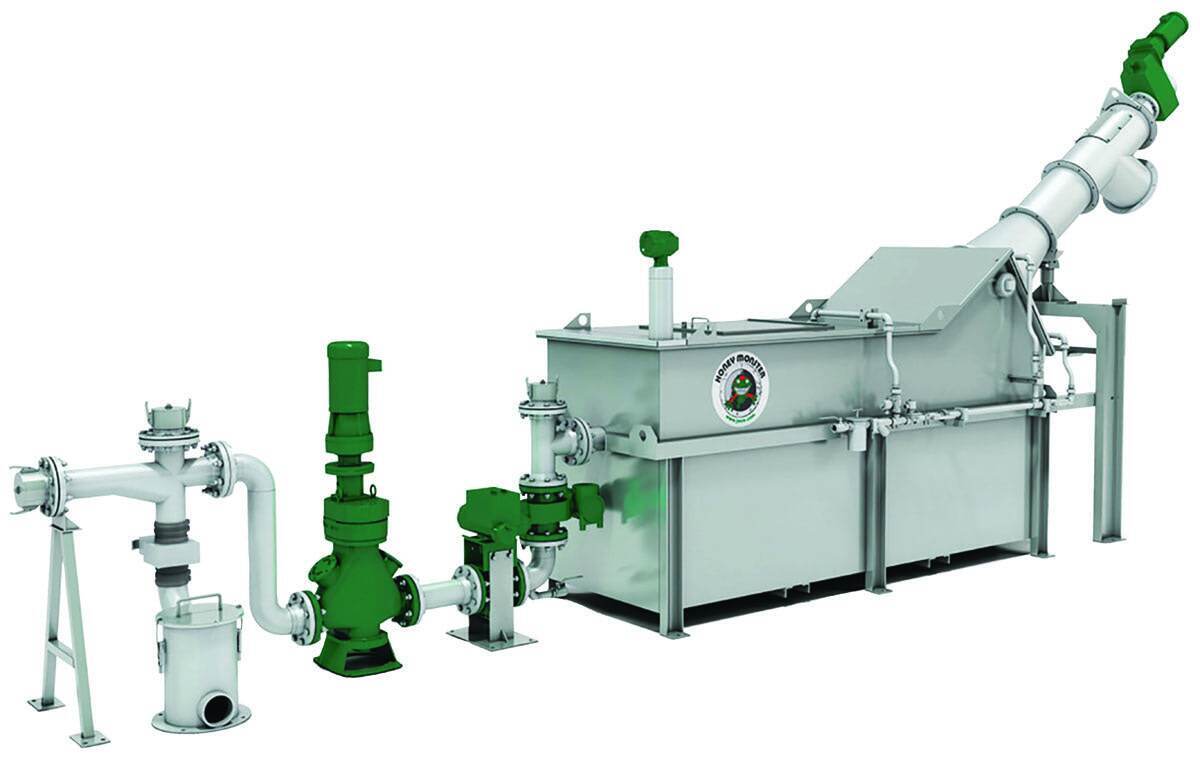

JWC Environmental Honey Monster

The Honey Monster septage receiving station and FOG receiving system from JWC Environmental is designed to ease the challenges of managing septage waste for the wastewater plant operator and the hauler. It quickly screens and processes septage, grease, FOG and sludge from vacuum trucks. This automated septage acceptance plant provides for cleaner handling of septage truck waste by reducing and separating unwanted solids such as rocks, rags, clothing, plastics and other troublesome trash, according to the maker. The combination of grinding, solids removal, washing and dewatering allows a typical septage truck to unload in 5 to 15 minutes. It is completely enclosed to ensure safety, vector control and containment of foul odors. The optional “MonsterTrack” metering and control system uses a flowmeter to track septage and provide accurate billing data for the facility and a receipt for the hauler. 800-331-2277; www.jwce.com.

ScreencO Systems Trash Master 400 Auto Screen

The Trash Master 400 Auto Screen from ScreencO Systems uses gravity to separate the trash from the flow stream through a 4-inch inlet with a fan spreader to power-offload vacuum trucks. It has an aluminum hopper with a 6-inch outlet cam and 3/8-inch gapped 1/4-inch bar screen that meets U.S. Environmental Protection Agency 503 regulations. A stainless steel U-channel with plastic-lined titanium UHMW provides for years of wear, with a high-strength alloy steel 8 1/2-inch shaftless screw that moves trash to a waste container. The stainless steel U-channel has slotted drain holes and a center channel bar screen for cleaner and dryer trash. A custom-built stainless steel bar rake is included for easy maintenance. A front spray bar with a 1 gpm nozzle keeps the unit clean and free of buildup. A 2 hp NORD gear reduction drive with Lenze variable-frequency drive control accomplishes a variable-speed screw from 6 to 30 rpms. 208-790-8770; www.screencosystems.com.