Dewatering Equipment

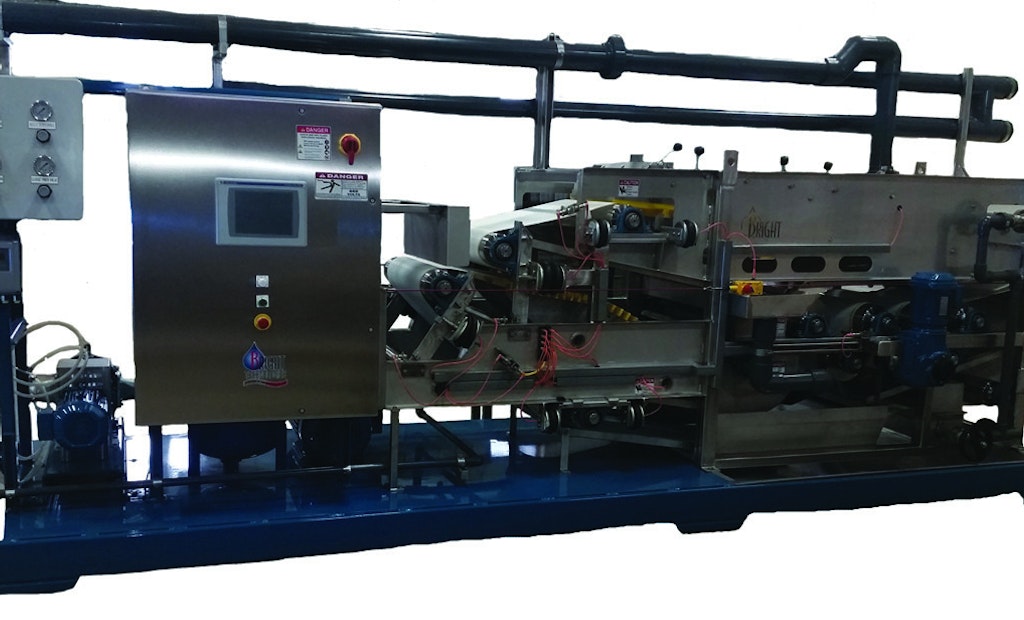

Bright Technologies, Division of Sebright Products, 0.6-meter skid-mounted belt filter press

The compact 0.6-meter skid-mounted belt filter press from Bright Technologies, Division of Sebright Products, has stainless steel frame and roller construction,...