Interested in Plumbing?

Get Plumbing articles, news and videos right in your inbox! Sign up now.

Plumbing + Get AlertsDespite increased attention to rollover prevention in recent years, these deadly accidents remain a major safety challenge for septic truck drivers. If you think you and your driver aren’t at risk, think again. These five myths about tank truck rollovers and safety resources can help you educate drivers on how to avoid rollovers.

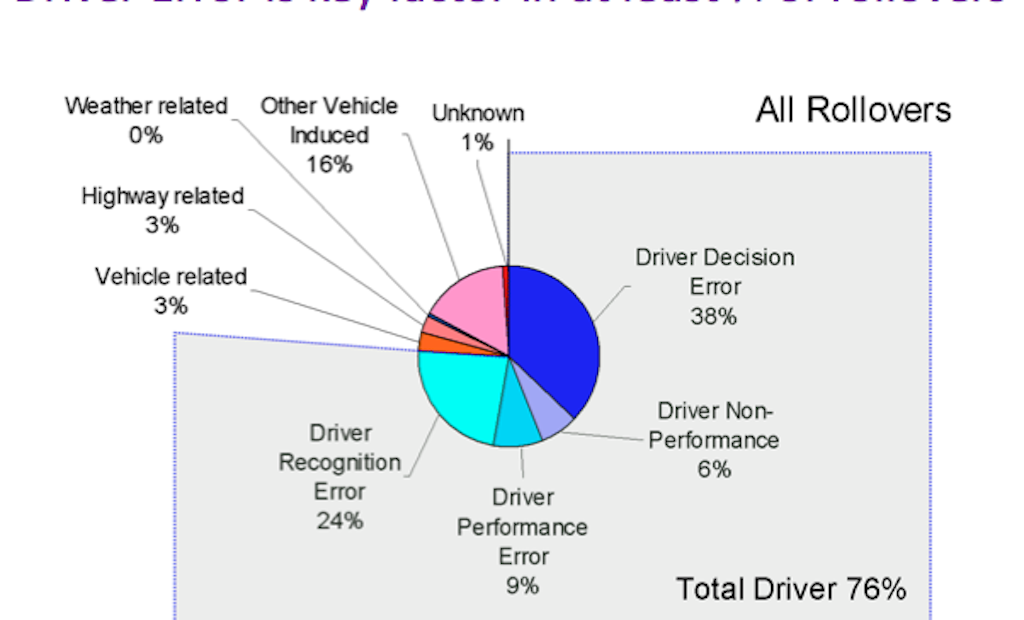

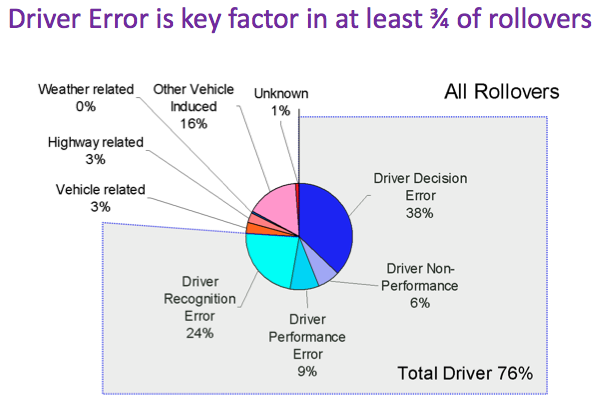

More than three quarters of these rollovers are the result of a driver action — or inaction. For instance, driving too fast for conditions and over-steering during an accident are two major causes of tank truck rollovers. The driver is the most important tool to eliminating rollovers. Use these myths in your next safety training session with tank truck drivers.

1. Tank tank rollovers are a semi-trailer problem

While tank semi-trailers are the most common tank vehicles on the highway and their crashes seem to dominate the headlines, the laws of physics do not differentiate among straight trucks, semi-trailers or truck-and-trailer combinations. When the liquid load in the tanker exceeds the rollover threshold, the vehicle will tip over.

25 percent of cargo tank rollovers involve straight tank trucks.

Perhaps one of the most surprising findings of a major report on tank truck rollovers from the Federal Motor Carrier Safety Administration (FMCSA) was that over 25 percent of cargo tank rollovers involve straight tank trucks. These crashes involve fuel oil trucks, septic tank trucks, propane trucks, milk trucks and fire department water tankers.

A number of factors impact straight truck rollovers:

- Straight trucks are more likely to be driven on less traveled or country roads.

- Many straight truck operations are seasonal and drivers may only operate part of the year.

- Straight trucks are more likely to travel with a partially loaded tank, which makes them more susceptible to rolling over.

- Anti-rollover devices — now widely specified on semi-trailers — are not available for straight trucks.

- Some straight trucks operate intrastate and do not receive the same level federal regulatory enforcement.

Perhaps a more subjective factor is that some septic truck drivers might think of themselves as solely a service technician for hauling waste rather than as a truck driver. Regardless of the other roles of the driver, when on the road that person is first and foremost a truck driver.

60 percent of straight tank truck rollovers occurred when the truck was going straight and 28 percent when the truck was negotiating a curve.

Think all rollovers happen during turns? The FMCSA report cites data from a Trucks Involved in Fatal Accidents study that found that 60 percent of straight tank truck rollovers occurred when the truck was going straight and 28 percent when the truck was negotiating a curve.

2. Most rollovers occur at highway ramps

Yes, the most visible rollover crashes — or those that receive the most media coverage — occur on exit or entrance ramps when the driver is moving from one road to another. Ramp rollovers, especially those causing septage spills, are likely to shut down major roads for prolonged periods.

However, even experienced tank truck safety professionals and regulators estimate 70 percent or more of rollovers occur at ramps. Wrong!

According to the FMCSA report, only about 8 percent of rollovers occur on ramps. While they tend to be more dramatic, attract more public and media attention, and cause more infrastructure damage, less than one in 10 occur on ramps.

Why? Perhaps the best answer is driver focus — or lack thereof.

On and off ramps are well marked with signs warning of potential danger. Posted speed limits require drivers to slow down. Experienced drivers know they should enter the ramp at no more than half of the posted speed.

Driver safety meetings and training should focus on the potential hazards of ramps. The “slosh” factor increases during a ramp maneuver, so extra attention is required.

The challenge for the tank truck industry is to train drivers to maintain the same focus throughout the trip that they have on a ramp. Try this: Start your next driver safety meeting with the question, “What percentage of rollovers occur on ramps?”

3. Rollovers are a “new driver” problem

While it is reasonable to focus on drivers who are new to driving a tank truck, experience has shown that even longtime drivers have rollovers. It takes a special driver to drive a tank truck.

Drivers who have operated the same equipment and hauled the same product over the same route for years can have a rollover. Complacency and over-confidence can affect a driver.

For instance, a veteran driver makes the same run hundreds of times, but he fills in for another driver on a Saturday rather than a weekday. A traffic light at the bottom of a hill that was always red on weekdays when he normally drove was green on that weekend. He was used to stopping at that light, but took the turn too fast when it was green and he — bam! — rolled the truck.

Supervisors should actively monitor driver behavior for these types of issues. Be sure drivers are aware of potential road or traffic light changes if they pick up additional routes or are running late during a regular run.

Don’t let drivers become complacent and develop bad habits!

Rollover prevention should be the subject of at least one safety meeting every six months. Invite drivers to share their experiences and near misses. What routes or locations cause special concern?

4. Anti-rollover devices prevent all rollovers

There have been advances in technology that can help prevent some rollovers, but there are no silver bullets that can prevent all rollovers. Most new tank trailers are equipped with some type of roll stability control (RSC) system. In fact, most manufacturers require a customer to state in writing if they do not want an RSC installed.

Don’t want to buy new? RSCs can easily be installed as a retrofit on older trailers.

RSCs can help alert the driver that he or she is reaching rollover threshold and in some conditions the systems will actually engage to control the vehicle when that threshold is reached.

The systems have proven successful in un-tripped rollover situations, such as on ramps, where lateral forces on the tires can cause a rollover. They are less successful in preventing tripped rollovers where another object or uneven ground is the challenge. They are not helpful in the over-steering-type rollover such as where the driver over-corrects when leaving the road surface.

Again, no piece of equipment can substitute for a well-trained and alert driver, but advances are being made to help address the tank truck rollover problem.

5. Most cargo tank rollovers are unpreventable

Driver error is the cause of at least 80 percent of tank truck rollovers. According to the FMCSA report, the most common cause of rollovers is the driver driving too fast for conditions, which does not necessarily mean exceeding the posted speed limits. Speed limits are for passenger cars. The driver is responsible for controlling his or her speed to adjust for traffic, terrain, weather and other factors.

The second most common driver error is driving off the road surface and steering too sharply in an attempt to recover. These crashes happen most frequently on curves. Two-thirds of cargo tank rollovers occur on undivided highways and most are single-vehicle crashes.

Almost all are a result of the driver not maintaining control of the vehicle to match its surroundings. Driver error can be either due to the driver’s action, such as driving too fast, or failure to take action such as to notice a change in traffic patterns or roadway.

Bottom line? Tank truck rollovers are preventable. There are many resources available to educate drivers individually or during safety meetings to help prevent rollovers:

- FMCSA offers a comprehensive Rollover Prevention Toolkit.

- Download the complete Battelle Cargo Tank Roll Stability Study.

- J J Keller has worked with National Tank Truck Carriers to develop a Cargo Tank Awareness program with posters and other materials designed to help prevent rollovers.

Don't worry, we've got you covered. Check out the safest septic trucks and tanks in the industry:

Vacuum trucks from Best Enterprises are built on a 2014 Kenworth chassis and use a 4,000-gallon stainless steel tank.

The LC 1500 from Ledwell is available in 900-, 1,500-, 1,750- or 2,000-gallon models, in carbon or stainless steel construction.

The newest vacuum truck from Pik Rite Inc. features internal plumbing for a clean look, a 20-inch rear manway with discharge valve and camlock fittings, a vacuum pump and more.

The Model 258 from Hino Motor Sales U.S.A. is well suited for portable restroom service.

The Princess II from Keith Huber Corporation is an easy-to-operate unit equipped with a high cfm vacuum pump, rear restroom carrier and four water-resistant cabinets with more than 30 cubic feet of storage space.

HANCO portable restroom service trucks from Southwest Products can be customized in a variety of sizes and configurations, and include dual-side service, custom lighting, restroom carriers and dual-compartment freshwater/waste tanks.

Among Vacuum Sales products are portable restroom service trucks. They feature rotary vane pump options that include models from Presvac, Fruitand, CVS and Jurop/Chandler.

The Flat Vac from Amthor International is a versatile multipurpose portable restroom tank truck.

The all-in-one rectangular vacuum waste tank from Crescent Tank Mfg., in sizes from 100 to 2,000 gallons, features a low-profile design with low center of gravity for hauling portable restrooms.

The PMT980 portable restroom service unit from Imperial Industries is a steel two-compartment tank, with a 680-gallon waste and 300-gallon freshwater capacity.

A portable sanitation unit from Mid-State Tank includes a 1,500-gallon stainless steel tank with 1,100-gallon waste and 400-gallon freshwater compartments installed on a 2011 Ford F-750 chassis.

Click here for complete product listings and manufacturer contact information.

About the Author

John Conley is past president of National Tank Truck Carriers and former editor of Modern Bulk Transporter magazine. He is president of ConleyComm LLC in Chester, Md. Contact him at concomm@atlanticbb.net.