Interested in Onsite Systems?

Get Onsite Systems articles, news and videos right in your inbox! Sign up now.

Onsite Systems + Get AlertsWhen it comes to dealing with odors at septage disposal facilities, biofilters are often the way to go.

Biofilters are cost-effective and operators can build one themselves, says Tom Ferrero, a project manager at FRANC Environmental Inc. and frequent speaker at national workshops and conventions on septic systems and wastewater issues.

Biofilters work by passing air through a medium that contains microbes. The microbes eat the odorous compounds, eliminating the odor from the air.

The key to a successful biofilter is keeping the medium – usually woodchips – moist and making sure there are pathways for air to flow through.

“It’s very high-tech, low-tech,” Ferrero says. “It’s high-tech since what the organisms are doing is pretty ingenious and low-tech since pretty much anyone can build one.”

Ferrero first became interested in biofilters in the 1990s when an engineer at his site in Elkart, Indiana, suggested constructing one to see how it could handle the odors. It worked.

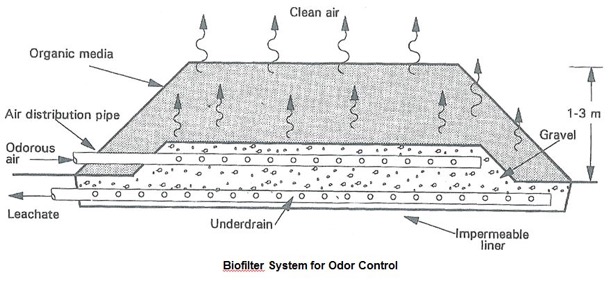

From there, he started using biofilters in different configurations and sizes. The main premise behind a biofilter is that odorous air is forced through organic material, where microbes convert it to carbon dioxide and water.

“Biofilters require long contact times between the medium – woodchips – and the air and the rate of the air needs to move at a low velocity,” he says. “They also have low setup costs.”

While there’s no one-size-fits-all design for a biofilter and operators can make adjustments based on their needs, there are some components that all biofilters should have:

While there’s no one-size-fits-all design for a biofilter and operators can make adjustments based on their needs, there are some components that all biofilters should have:

- An impermeable liner beneath the entire area where the biofilter will be constructed to protect the soil underneath. Some operators build one in a large container.

- An air distribution pipe to bring in the odorous air.

- Humidity. The inlet air should be at least 80 percent.

- A blower to keep the air moving.

- Several feet of organic material, usually woodchips.

Ferrero says the woodchips or whatever medium is used in the biofilter should be replaced every five years or so because as the organic matter decomposes it gets denser, requiring more pressure to move the air through the biofilter.

Biofilters do have a downside: they require a large land area. A typical one has a footprint of 50 feet and is about 4 feet high.

But, Ferrero says, “Building a biofilter is easy and once you have one, they are easy to maintain.”