Interested in Disposal?

Get Disposal articles, news and videos right in your inbox! Sign up now.

Disposal + Get AlertsTraditionally, machinery shop floors have been drained by various grated drain systems that consistently clog up and require frequent maintenance to keep the drain operational. Norstar Industries Ltd., a company based out of southern Manitoba, Canada, is revolutionizing the industry with a product called U-Drain. U-Drain is a single-slot, non-grated, pre-engineered floor drain that offers the most cost-efficient and low-maintenance drainage solution available on the market.

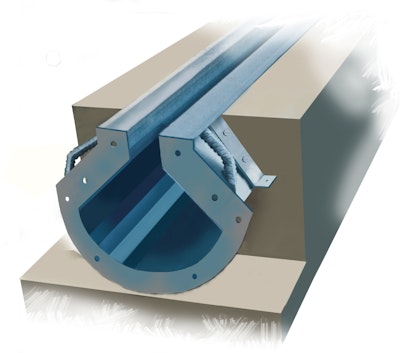

When using U-Drain, surface water is removed by passing through the drain slot and into the pre-sloped trench which brings the water to the drain sump. The 1-inch slot (for commercial models) is level with the floor and acts as the intake of the drain. This simple design is what makes U-Drain stand out. “There are no grates involved,” says Norstar representative Cody Quiring. “The slot opening requires much less maintenance than traditional grated systems. Not only do you not have as much garbage getting caught in the intake, but the sloped design of the drain renders it a self-cleaning system, cutting down on maintenance and making the drain more sanitary.”

A basic U-Drain system consists of an endcap, 10-foot pre-sloped or non-sloped sections (depending on the model) and a drainage sump. “It’s a very simple system,” states Quiring. All U-Drain parts are bolted together and easily attach to complete the system.

The installation process of the U-Drain is simple and straightforward. The system is installed into a concrete floor, generally at the beginning of the building process (retrofits are possible). The U-Drain system is laid into an excavated trench that allows for concrete to be poured around the drain and sump. The drain is designed in such a way that it connects directly to the rebar grid prior to the pouring of the concrete. When securely installed, the top of the U-Drain should be flush with the concrete level.

When asked about the structural stability of the system, Quiring explains, “U-Drain is engineered in such way that the weight load is transferred through the drain and into the concrete below. As long as the system has been properly installed, the drain is as strong as the concrete surrounding it.” This structural design ensures that the U-Drain can withstand heavy, high-traffic applications, making it a perfect fit for machinery shops.

U-Drain is manufactured with a galvanized finish, protecting the drain from deterioration and rust. Stainless steel options are available as well. Norstar offers a number of different types of sumps for the U-Drain, including an oil separator sump which promotes an environmentally friendly drainage process.

U-Drain offers a simple and efficient drainage solution to the market, providing a versatile option for customers in various situations. “The key feature with U-Drain is that it is such a flexible system,” notes Quiring. “You can set up a 10-foot section, a 30-foot section or a 150-foot section. The possible applications are endless, and it really depends on what the customer needs.”

For more information on U-Drain Floor Drainage, visit www.u-drain.ca.