Interested in Pumps?

Get Pumps articles, news and videos right in your inbox! Sign up now.

Pumps + Get AlertsThe positive displacement blower was introduced as a more efficient water wheel. Made of wood, it was put in the millstream and as the water flowed through it, the rotors turned and power was generated for milling from the output shaft. It worked well except for a minor flaw; the wood would swell up and ruin the clearances and the mill would stop. The unit would be taken out of service and dried out, shrinking the parts to their original dimensions.

In an effort to speed up the drying, as soon as the rotors would turn, a power source could be connected to the output shaft and the rotors spun. Someone noticed that the arrangement would move a large quantity of air and the use as an air blower began.

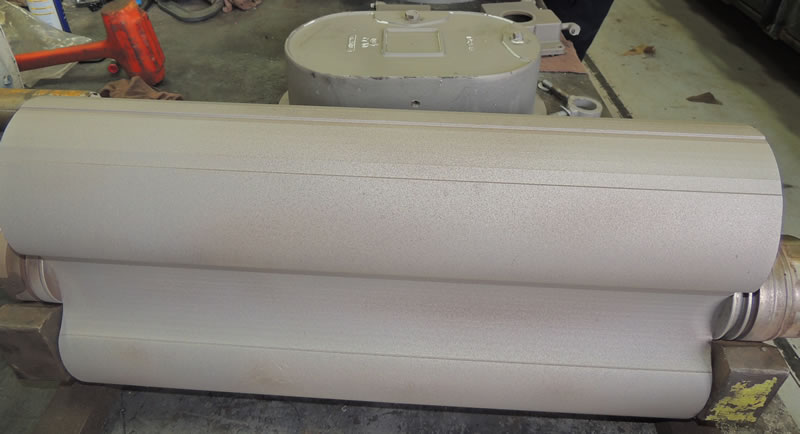

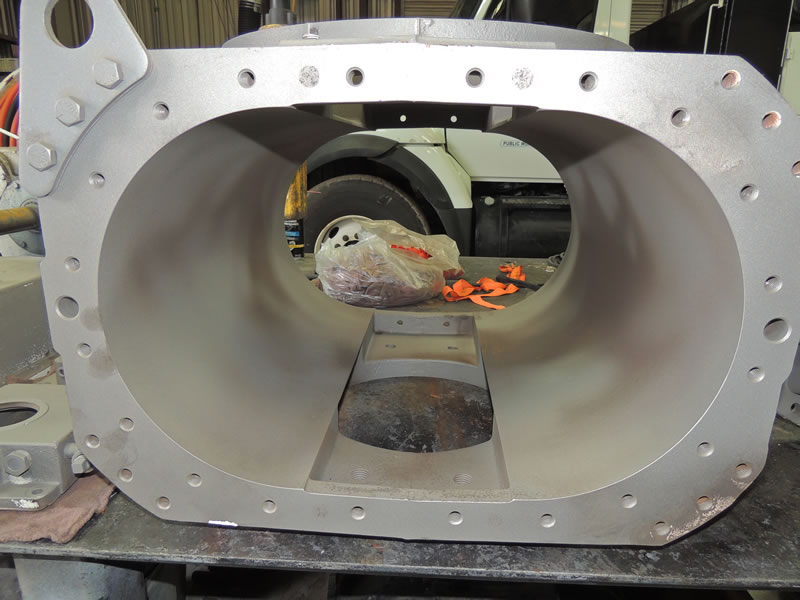

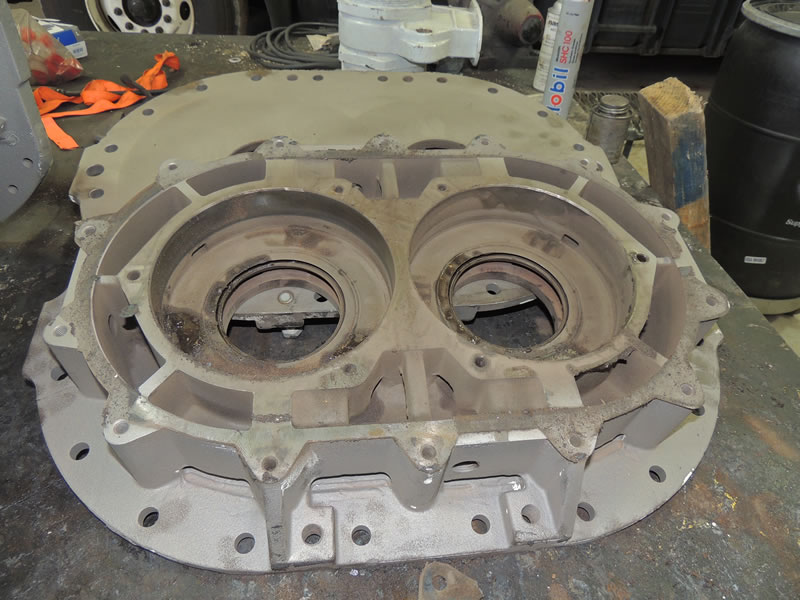

Positive displacement blowers are one type of vacuum system used by Vac-Con (other than a fan system). The one key aspect of a PD blower is the close tolerance that exists between the lobes. The distance between the two blower lobes at their closest point is about .0007 of an inch, which is maintained by a ridge on the top of the lobe called a land. Over time the land can become smaller which opens up the tolerances between the lobes, reducing the amount of vacuum the blower has.

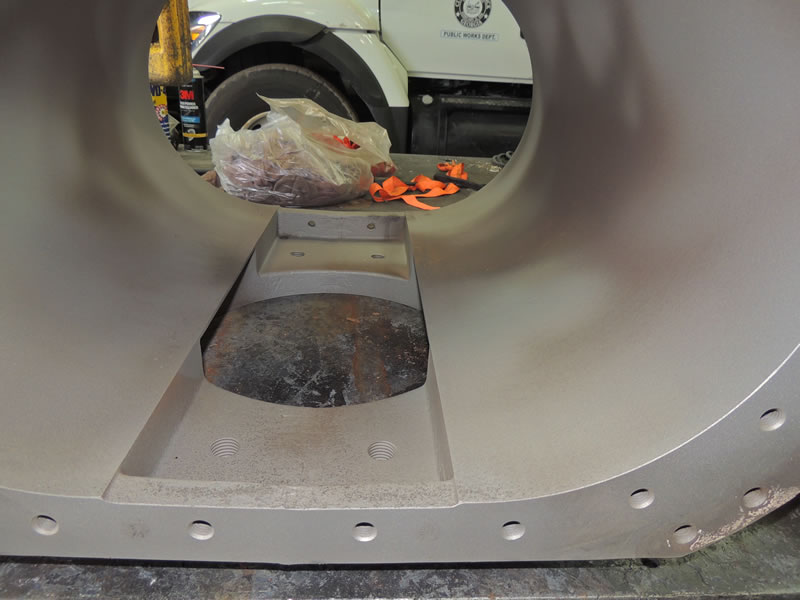

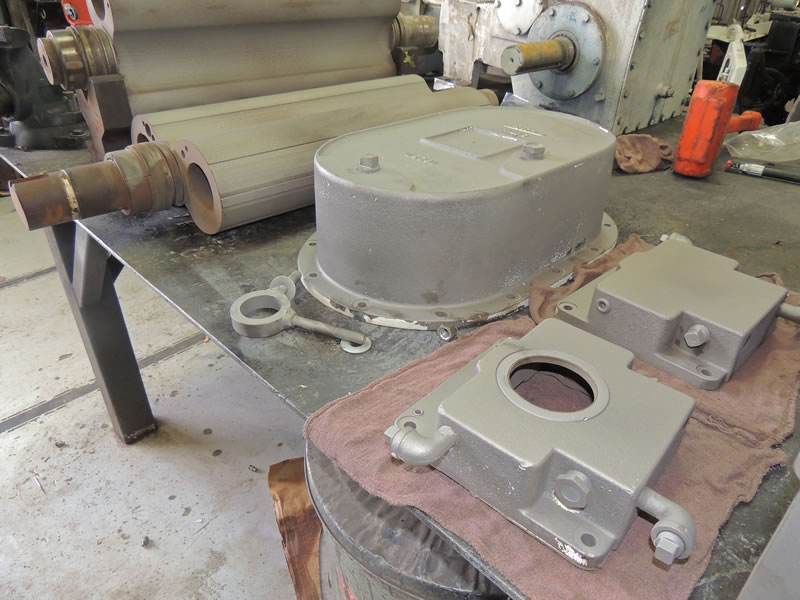

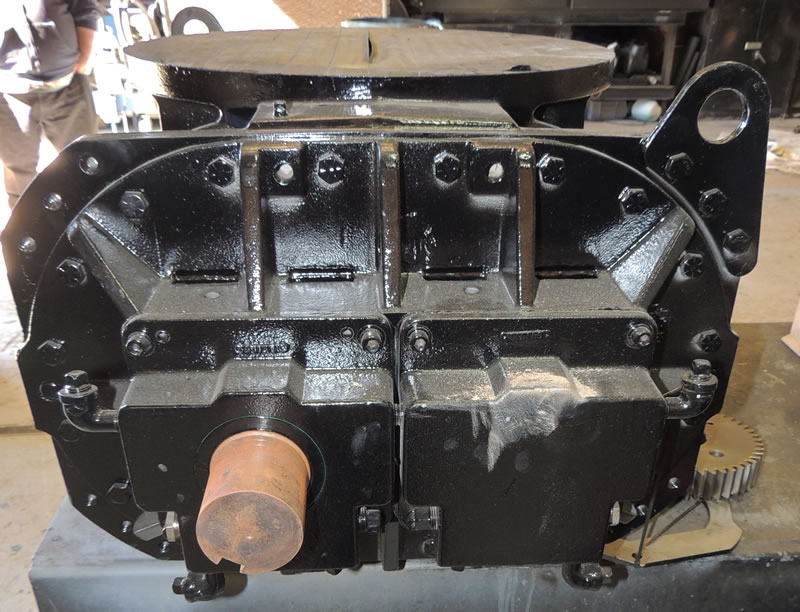

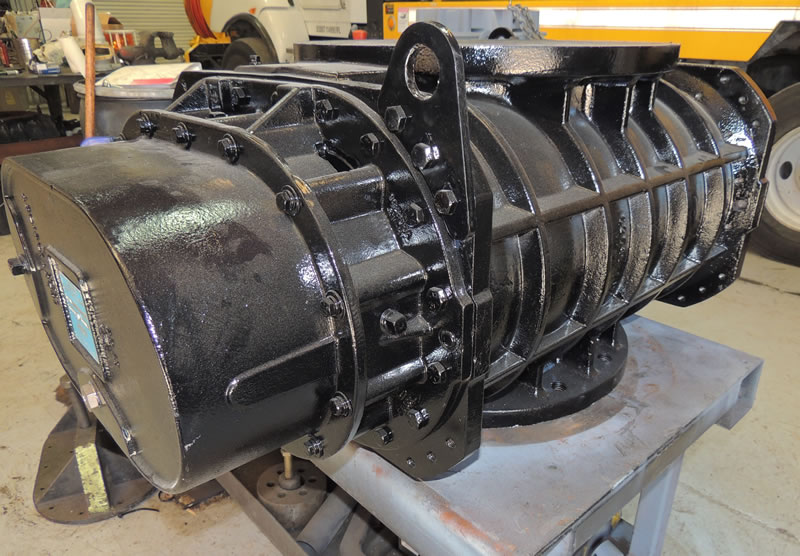

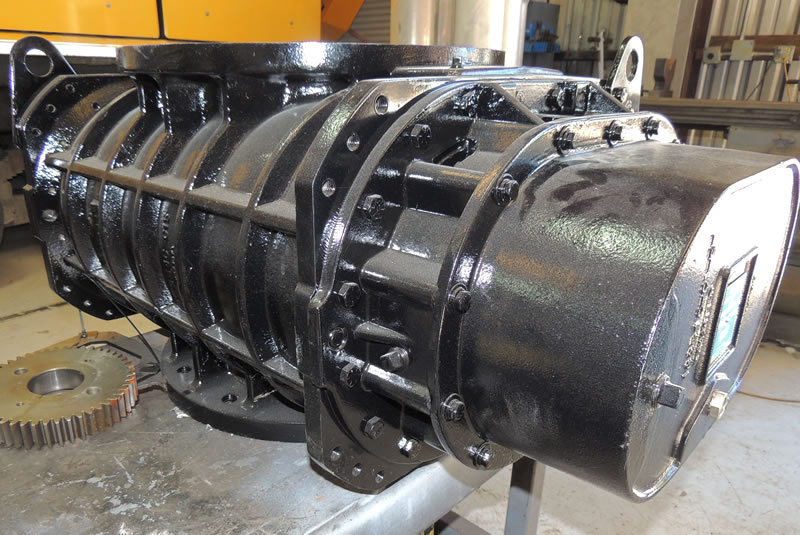

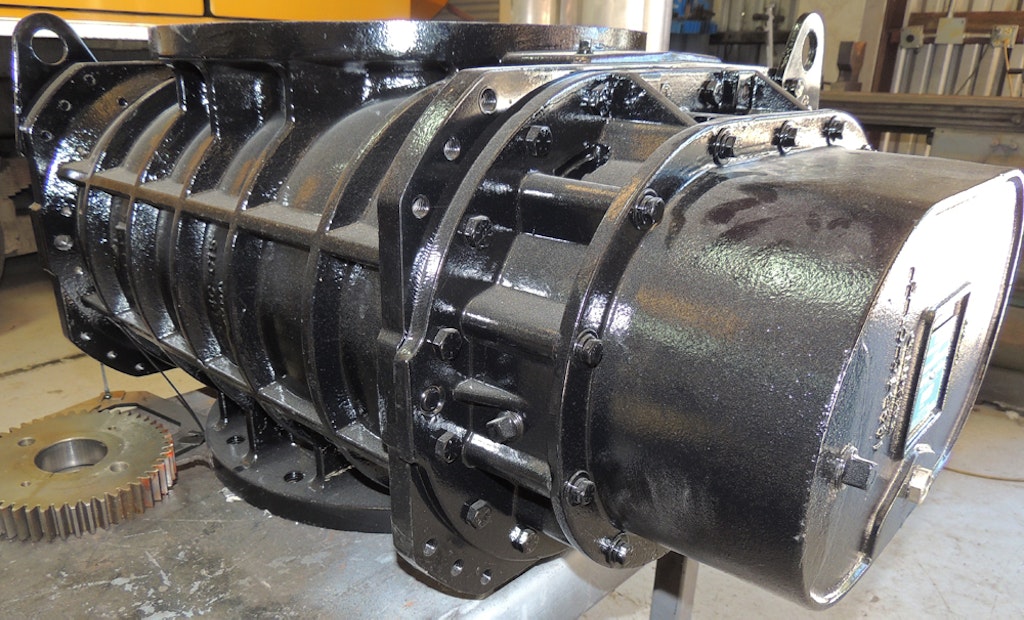

During the blower refurbishment process the lobes are removed and refinished. The land has to be rebuilt using a special welding rod and then machined back down to factory specifications. All of the cast parts are machined and refinished before reassembly.

During the reassembly process all of the bearings and seals are replaced. At the end of the whole process, the blower is a like new machine.

This photo slideshow shows a positive displacement blower refurbishment from beginning to completion.

For more information, visit www.vac-con.com.