Sand filtration system a fit for property

with shallow water table

Problem: An owner in North Smithfield, Rhode Island, needed to replace a cesspool for a two-bedroom home so the property would pass a time-of-sale inspection. The property had a shallow water table, and all setbacks had to be met for a code-compliant system. The builder wanted the system to be installed below grade so it wouldn’t detract from the curb appeal.

Solution: D.H. Keene Septic designed the system and chose Eljen GSF (Geotextile Sand Filter) B43 modules for the drainfield because of the reduction in footprint size and shallow profile compared to a traditional system. The 80-foot-long by 4-foot-wide trench was placed within the setbacks of the property line and well by Matt Osborne and Dan Marcotte from Ken’s Excavating. A tipping distribution box delivers effluent to the 18 GSF modules from new 1,000-gallon septic tank.

Result: The home has a code-compliant system installed quickly so the property could be sold. The GSF system was installed in a smaller footprint than a stone-and-pipe system but requires the same maintenance. 800-444-1359; www.eljen.com.

Grinder pumps used to keep

sewer pump system clear

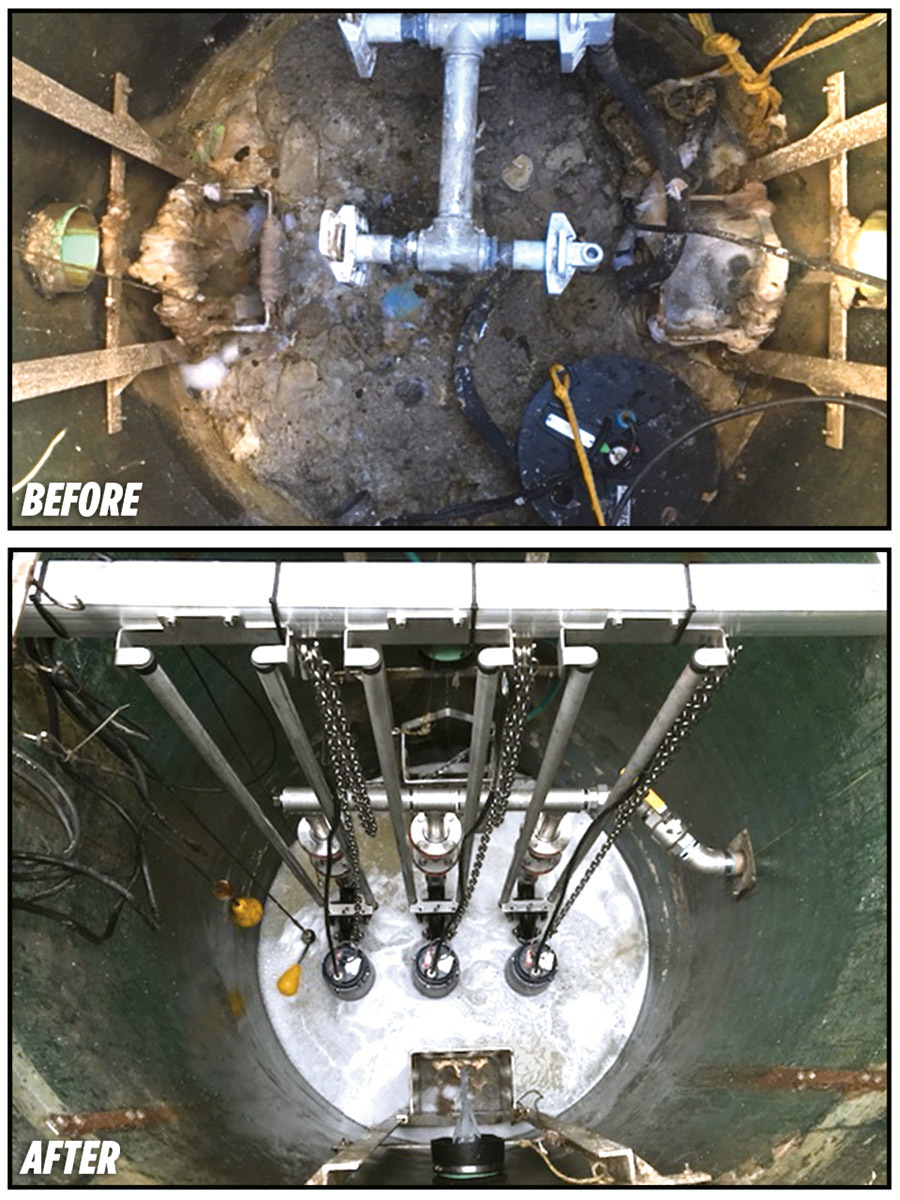

Problem: At least once a month, residents of a New Jersey townhome complex saw a familiar sight: a septic truck unclogging their sewer pump system and cleaning out the well. The multifamily complex utilized a four-pump system originally engineered for single-family homes, and it was seriously underperforming with a limited pumping capacity of 11 gpm. This caused rags and solids to accumulate in the basin, and frequent vacuum truck visits to keep the system operational.

Solution: With the cost of emergency repairs and quarterly maintenance adding up, the facility turned to Franklin Electric’s FPS IGP Series grinder pumps. Designed as a direct replacement for small-horsepower progressive cavity and other centrifugal grinder systems, the 2 hp pumps could easily tackle larger jobs. With a maximum flow rate of up to 33 gpm, the quadplex system was simplified to a triplex. These pumps were also designed for retrofit applications, allowing the owner to keep the existing basin and modify the controls. In addition, the pumps were installed on a guiderail. When routine maintenance is required, service techs can easily slide the pumps out of the well, streamlining pump cleaning.

Result: Installed in 2018, the system has never clogged, eliminating monthly septic truck visits and maintenance and emergency repair costs. 800-348-2420; www.franklinengineered.com.