Interested in Portable Sanitation?

Get Portable Sanitation articles, news and videos right in your inbox! Sign up now.

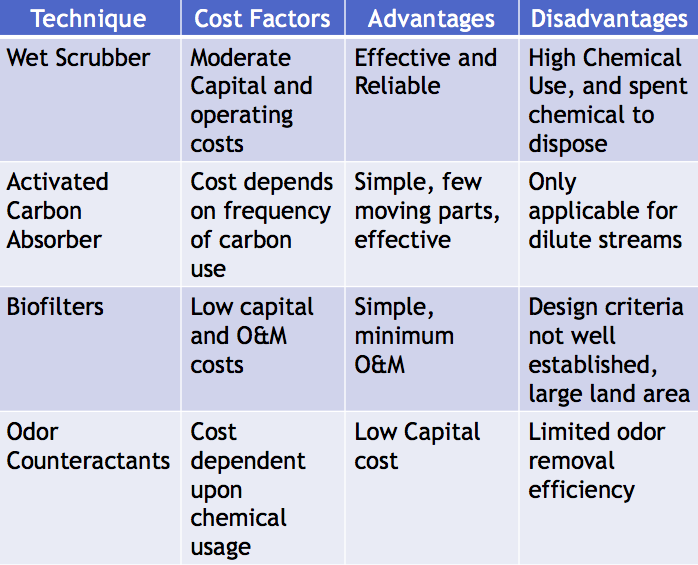

Portable Sanitation + Get AlertsWhen it comes to containing odors, there are many options to consider, and they don’t all work equally well for every situation.

Tom Ferrero, a project manager at FRANC Environmental Inc. and frequent speaker at national workshops and conventions on septic systems and wastewater issues, says operators can choose from techniques including misting, installing biofilters and using a wet scrubber or activated carbon absorber to tackle the issue.

“There are multiple ways to address odors, including just being away from everyone else at a remote location,” he says. “That doesn’t really deal with the odors. You’re just not bothering your neighbors.”

While each of the other options — misting, wet scrubbing, activated carbon and biofilters — have their pluses and minuses, Ferrero prefers using biofilters to deal with odors.

“Biofilters are cost-effective and work the best,” says Ferrero, who served as executive director of NAWT before joining Philadelphia-based FRANC Environmental.

In biofilters, microorganisms break down the pollutants. “The big advantage with biofilters is how simple they are.”

While Ferrero is a big proponent of biofilters, he says the other methods do have their place. For example, activated carbon absorbers are effective in handling odors from smaller operations.

“If you don’t have a lot of activity, odors will be more minimal and that works.”

Activated carbon sets itself apart since it does not require water or chemicals and doesn’t use a lot of energy, Ferrero says. The key with activated carbon is that it works best in small areas, so it would not work well in a system with a large flow rate.

A downside is that it cannot adequately treat a sludge area. If a sludge area is present, wet scrubbers or biofiltration are necessary to handle the larger flow rate.

“Activated carbon filters have few moving parts, which is another advantage,” Ferrero says.

As for cost considerations, it really depends on how much carbon is used, he adds.

With wet scrubbers, the advantage is they can handle higher flow rates and pollutant concentrations, Ferrero says. They are also effective and reliable.

“A definite downside to wet scrubbers is they use a lot of chemicals and then you have to deal with disposing those chemicals,” Ferrero says.

Operators who opt to use the misting process can reduce their odors by 30 to 40 percent, Ferrero says. Misting, which involves spraying odor counteractants into the air, works by encapsulating the odorous compounds. A major misting downside, however, is the cost of the chemicals being used and concerns about putting so many chemicals into the air.

Next week: Building a biofilter