Interested in Industrial?

Get Industrial articles, news and videos right in your inbox! Sign up now.

Industrial + Get AlertsHas your pump lost its pop? Are there strange noises coming from inside the housing? Perhaps it’s time for a rebuild or even a new vacuum pump.

Dave Flagg, Moro USA president and CEO, says telltale signs of a failing pump include loss of vacuum, loud bearing noises and worn vanes.

“There are inspection holes on the side of the vacuum pump where you can check vane wear and determine if it’s time to replace them,” he says. “You want to replace them before they get too short and snap off.”

Signs of failure include cupped rather than straight vanes and the time it takes for the pump to draw vacuum. Flagg recommends checking your owner’s manual for suggested maintenance and repair.

Different pump, different rules

If it’s time for a rebuild, look for a kit with the necessary gaskets, seals, vanes and bearings to get the job done.

Not every pump can be rebuilt, Flagg says.

“The thing to look for when you’re rebuilding a pump is if there’s any washboarding in the main housing. In that case, you want to bore the pump out,” he says. “Say you’re running at a low rpm and the vanes begin to bounce inside the pump; it’s like ripples in the river. The vane will jump across that washboarding, and when that happens you will lose performance. You need to make that housing a smooth, round bore again before you put the rebuild kit in there.”

Rotary vane pumps are easily rebuilt, and with proper care can last for decades.

“They don’t always get destroyed by running product through there,” Flagg says. “We get some in here that are easily 10 or 15 years old because of the high-quality casting.”

Need a fresh start?

“Like an engine cylinder, the bore can only go to a maximum diameter, and if it’s washboarded or worn beyond the point of that maximum diameter, you need to replace the pump,” he says.

“If you’ve got a pump that’s 20 years old, some of the other parts also will begin to wear out. With a new pump you’re starting out fresh.”

When deciding on a new pump, performance and technology are two factors to consider.

“It may be a cantered rotor versus a straight rotor, maybe a different type of check valve,” Flagg says.

Or perhaps you’ve expanded your service offerings and need more vacuum.

If you’re pumping septic tanks for a short period of time, a naturally air-cooled pump will work just fine, Flagg says. But if you’re pumping heavier materials over longer distances or to higher elevations you might consider upgrading to a fan- or liquid-cooled pump.

“That smaller pump might not be able to handle the job as well,” he says. “Let’s say today you’re Joe Septic and you’re pumping septic tanks and most of your runs are 100 feet and 3-inch hose. You can do that with any pump.

“But now your business model has changed and you’re doing a lot of work for municipalities and you have to pump deeper in the ground, say a wet well or a lift station. You need more vacuum. Your pump will have to run longer. If you have just an air-cooled pump, it’s not made to run seven or eight hours at a time.”

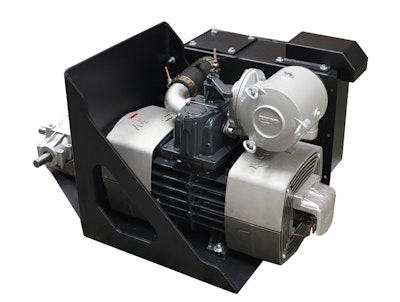

Whether you plan to rebuild or want to invest in new, here are some vacuum pumps to choose from:

- The Jurop RV360 rotary vane vacuum pump from Jurop/Chandler offers efficient dual-fan cooling technology and quiet operation.

- The General Pump MW Series offers five plunger sizes to cover flow ranges from 36 to 105 gpm and pressures up to 4,350 psi.

- The Berringer liquid-ring pump unit from Keith Huber Corporation provides 1,000 cfm of vacuum and high-velocity air induction with a pressurized push-button tank discharge.

- The HXL400WV heavy-duty, water-cooled pump from Masport is designed for septic pumping use.

- The PM3000 Storm Series liquid-cooled vacuum pump from Moro USA is capable of pumping nonvolatile liquids and sludge from long distances, providing an additional choice for heavy-duty industrial applications with a suggested tank capacity of 3,000 to 6,000 gallons.

- The Bolt and Go from Surpresseur 4S features a range of Robuschi RB-DV 28-inch HgV high-vacuum blowers from 500 to 2,600 cfm.

- The 753 Series vacuum pump from Wallenstein Vacuum Pumps incorporates extra-wide vanes that allow up to an inch of wear, resulting in longer service life with lower maintenance costs.

- Conde Powerpak preassembled, gasoline- or diesel-powered vacuum pump units from Westmoor Ltd. are easily installed by bolting and attaching them to the tank.